- Joined

- Oct 19, 2020

- Messages

- 158

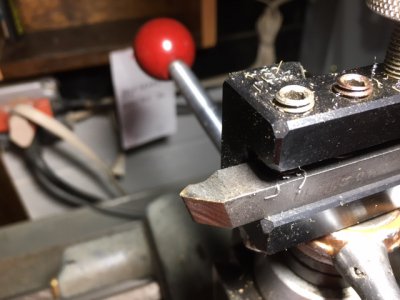

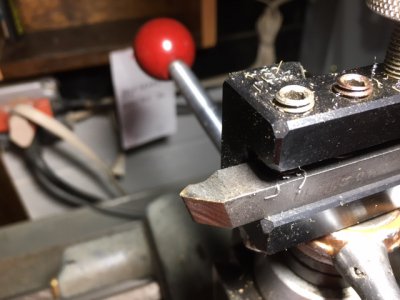

One of the hardest things for me to learn since I purchased my lathe almost 2 years ago is how to grind my lathe tools. I have been working with HSS and concentrating on the right hand turning tool. I have made a couple of them with Mr. Pete's tutelage. When it comes to facing, my right hand turning tool seems to work just fine. I just angle the compound and Bob's your uncle. What am I missing?

I'll attach a few pictures of my grinder and my right hand turning tool.

I'll attach a few pictures of my grinder and my right hand turning tool.