- Joined

- Sep 3, 2023

- Messages

- 222

Yes, Charlevoix Yacht Club. I raced the Red Fox there one year on a beautiful J 109

View attachment 460434

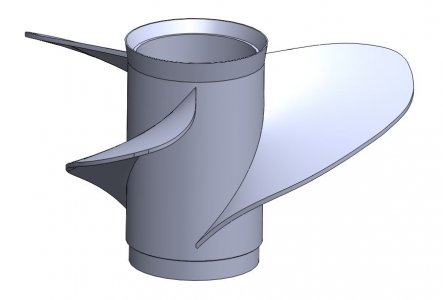

How long have you been sailing? My friend used to have a company that made sail boat parts. Spinnaker masks, I think. I used to make parts and help put them together. I think his company was Amco Marine, or something like that. It been a long time ago.

Sent from my iPhone using Tapatalk