- Joined

- May 7, 2015

- Messages

- 269

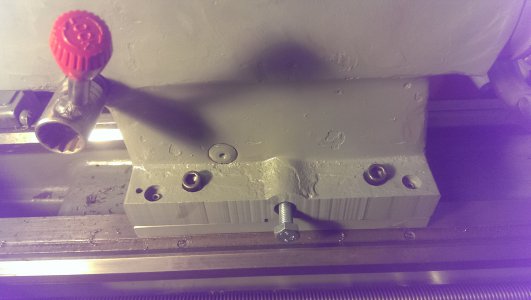

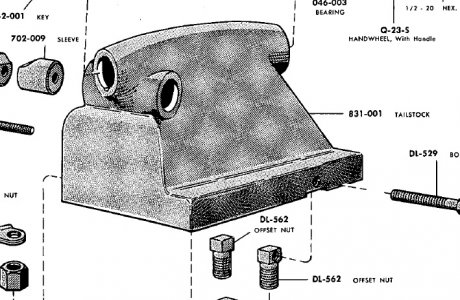

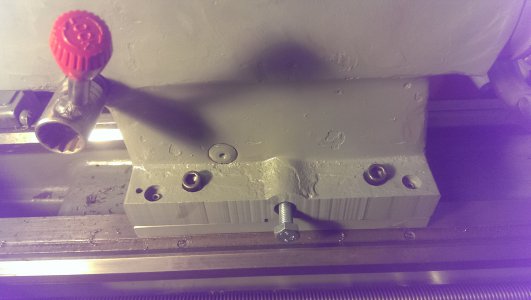

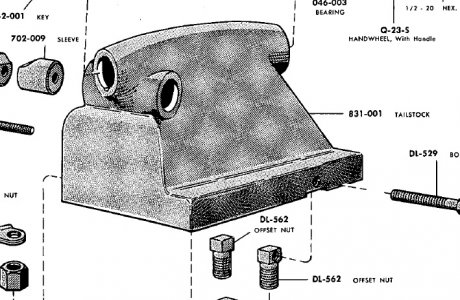

Hey guys, On the tail stock of my 6316 I have two socket head bolts that appear to be some kind of pinch bolts. They tighten down a split section of the tail stock. I have looked at the drawings I have an they are not present.

I am trying to adjust my tail stock, using the side adjustment bolts. Just wondering if these need to be loosed to adjust the side to side movement of the tail stock quill and then need to be tightened after the adjustment.

Enclosed are some pics of my tail stock and the drawing assembly of the tail stock.

Thanks

Joe

I am trying to adjust my tail stock, using the side adjustment bolts. Just wondering if these need to be loosed to adjust the side to side movement of the tail stock quill and then need to be tightened after the adjustment.

Enclosed are some pics of my tail stock and the drawing assembly of the tail stock.

Thanks

Joe