- Joined

- Oct 17, 2018

- Messages

- 922

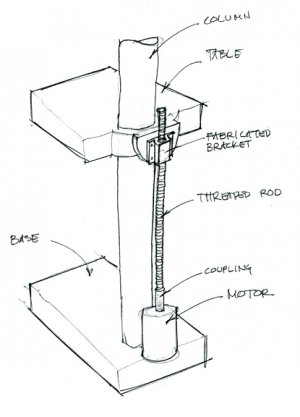

I have a design idea for a table raising mechanism for my Craftsman drill press. How would I know what type of motor to buy? Specifically, what torque spec am I looking for? I'm not sure how to go about calculating it. Here is the design idea:

The motor is mounted at the bottom (haven't figured that out yet, so it's not in the sketch) and is stationary. It has a threaded rod (1/2" diameter, maybe) attached that spins. There is a fabricated bracket attached to the table that has a threaded hole that the rod rides in, lowering and raising the table as the shaft spins.

I'll run a switch from the motor to either a foot pedal or rocker switch, I haven't decided yet. I want to figure out what motor to use.

I was going to use a drill, but a motor mounted on the drill press seems like a better design. A 5A drill has about 3/4 HP or so, which I think is about 412 lb/ft of torque? Do I have that right? Is that enough?

The table weighs about 30-50 lbs and needs lubrication on the column to move better, but it does slide up and down with some effort.

McMaster-Carr has motors, but the specs are all over the place, as are the prices. I'd like some help figuring out what I need. Thanks!

The motor is mounted at the bottom (haven't figured that out yet, so it's not in the sketch) and is stationary. It has a threaded rod (1/2" diameter, maybe) attached that spins. There is a fabricated bracket attached to the table that has a threaded hole that the rod rides in, lowering and raising the table as the shaft spins.

I'll run a switch from the motor to either a foot pedal or rocker switch, I haven't decided yet. I want to figure out what motor to use.

I was going to use a drill, but a motor mounted on the drill press seems like a better design. A 5A drill has about 3/4 HP or so, which I think is about 412 lb/ft of torque? Do I have that right? Is that enough?

The table weighs about 30-50 lbs and needs lubrication on the column to move better, but it does slide up and down with some effort.

McMaster-Carr has motors, but the specs are all over the place, as are the prices. I'd like some help figuring out what I need. Thanks!