- Joined

- Aug 13, 2020

- Messages

- 1,342

I posted about the 3phase motor I got off a treadmill down below. 5 "treadmill" Hp == 1.5 actual Hp was the conclusion I came to after y'all educated me.

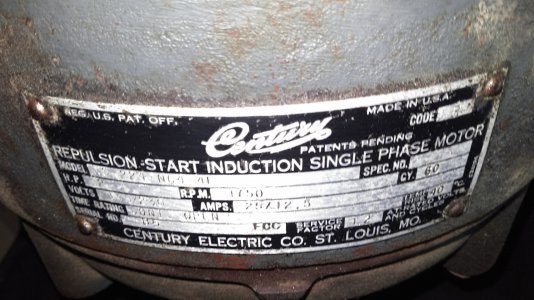

Now that I have the late-1942 era Sebastian in the workshop and setup, I'm taking a closer look at the motor it came with. Best I can tell, it is the original. At least it matches the drawings that the Navy produced for the lathe. This motor can be wired to run 115V or 220V. I went with 115V, 'cause that is what my shop is wired for, but the motor is name-plated for 25A at that voltage.

Have I just consigned myself to constantly resetting a 20A breaker? Or would that only happen if I'm pushing the system REALLY hard? What is the ultimate limit for power draw in a motor? IE, if I locked the shaft and switched it on, would the winding's resistance limit it to 25A, or is that what you'd measure right before the windings melt and all the smoke came out of it . . . which is what I believe will happen if you lock the shaft?

Safety: I wired the circuit with 12AWG, so I could just switch out for a 25A or even 30A breaker, and never have to worry about it. . . but, I wouldn't be any smarter at the end of the day if I did that.

Now that I have the late-1942 era Sebastian in the workshop and setup, I'm taking a closer look at the motor it came with. Best I can tell, it is the original. At least it matches the drawings that the Navy produced for the lathe. This motor can be wired to run 115V or 220V. I went with 115V, 'cause that is what my shop is wired for, but the motor is name-plated for 25A at that voltage.

Have I just consigned myself to constantly resetting a 20A breaker? Or would that only happen if I'm pushing the system REALLY hard? What is the ultimate limit for power draw in a motor? IE, if I locked the shaft and switched it on, would the winding's resistance limit it to 25A, or is that what you'd measure right before the windings melt and all the smoke came out of it . . . which is what I believe will happen if you lock the shaft?

Safety: I wired the circuit with 12AWG, so I could just switch out for a 25A or even 30A breaker, and never have to worry about it. . . but, I wouldn't be any smarter at the end of the day if I did that.