- Joined

- Feb 1, 2015

- Messages

- 9,622

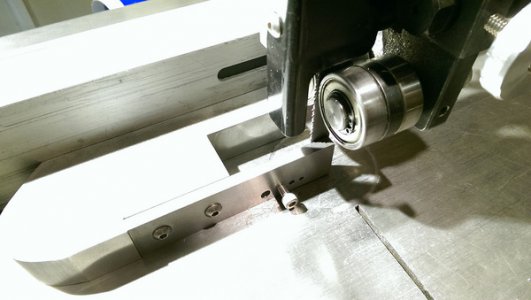

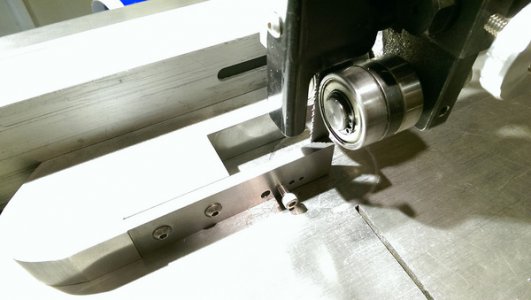

For larger bolts, I thread on a nut and mount the bolt in the lathe chuck, using the head and the nut as bearing surfaces. The bolt can be shortened with a parting tool or other lathe tool or with a hack saw. If using a hack saw, leave the lathe off and place a piece of sheet metal, plywood, etc. to protect the ways. After shortening the bolt, I will face the cut surface and use a file to chamfer the end. If you don't mind the sawn surface, the chamfering process will remove any burrs.

For smaller bolts, I use the screw shear function on the wire stripper, as stated by Mark above. One trick that I had used on my wire stripper was to run a tap through it while applying a slight pressure. This cut partial threads into the shearing jaw which tends to prevent the jaw from splaying out and has less chance of deforming the freshly cut thread. After shearing, I will advance the screw about 1/4 turn and shear again. This removes the burr on the far end, giving clean thread.

Edit: The first paragraph should say for larger hex head bolts. If I am cutting a socket head cap screw, I would use three nuts with the third nut being a lock nut to prevent the bolt from rotating while cutting or dressing. If cutting something like a carriage bolt with a head larger than the distance across the flats, I would use a split bushing, as suggested above, to hold the bolt securely.

For smaller bolts, I use the screw shear function on the wire stripper, as stated by Mark above. One trick that I had used on my wire stripper was to run a tap through it while applying a slight pressure. This cut partial threads into the shearing jaw which tends to prevent the jaw from splaying out and has less chance of deforming the freshly cut thread. After shearing, I will advance the screw about 1/4 turn and shear again. This removes the burr on the far end, giving clean thread.

Edit: The first paragraph should say for larger hex head bolts. If I am cutting a socket head cap screw, I would use three nuts with the third nut being a lock nut to prevent the bolt from rotating while cutting or dressing. If cutting something like a carriage bolt with a head larger than the distance across the flats, I would use a split bushing, as suggested above, to hold the bolt securely.

Last edited: