- Joined

- Feb 24, 2024

- Messages

- 6

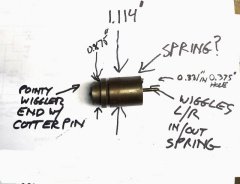

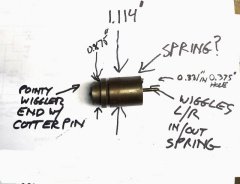

Perhaps someone can tell me what this item is. It's another one of the items in grandad's collections of tools, stored with the Atlas10D and the Craftsman drill press. Both have milling attachments.

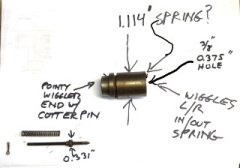

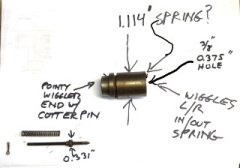

The "wiggler" is pointy and spring loaded to push outward, but retracts into the body. It's sort of like a tap follower. The shaft, about 1/8" diameter, slides out the back end and is retained by a cotter pin. The rear hole is close to 1/8" diameter, but the main axial hole (3/8") is much larger than the 0.331" diameter on the wiggler shaft (which retains the central spring). As a result, the sharp tip wiggles up/down, left/right by about 1/4".

I thought about a tap follower or a wiggler for aligning a center punch mark on the rotating work with the tailstock axis? Neither seems right.

There is a second spring (about 1/4" diameter) stuck into an off axis hole parallel to the main axis. It's much stronger than the first spring, and may be broken off. It won't come out of its hole.

The pointy end is to the right. The left end with the cotter pin is squared off and the shaft moves about 1/2" into the piece.

Photo 1 is assembled, 2 disassembled.

Any thoughts on this item? Thanks for any help, (and thanks for the comments on item 1 in my previous post.)

The "wiggler" is pointy and spring loaded to push outward, but retracts into the body. It's sort of like a tap follower. The shaft, about 1/8" diameter, slides out the back end and is retained by a cotter pin. The rear hole is close to 1/8" diameter, but the main axial hole (3/8") is much larger than the 0.331" diameter on the wiggler shaft (which retains the central spring). As a result, the sharp tip wiggles up/down, left/right by about 1/4".

I thought about a tap follower or a wiggler for aligning a center punch mark on the rotating work with the tailstock axis? Neither seems right.

There is a second spring (about 1/4" diameter) stuck into an off axis hole parallel to the main axis. It's much stronger than the first spring, and may be broken off. It won't come out of its hole.

The pointy end is to the right. The left end with the cotter pin is squared off and the shaft moves about 1/2" into the piece.

Photo 1 is assembled, 2 disassembled.

Any thoughts on this item? Thanks for any help, (and thanks for the comments on item 1 in my previous post.)