- Joined

- Dec 23, 2019

- Messages

- 1,138

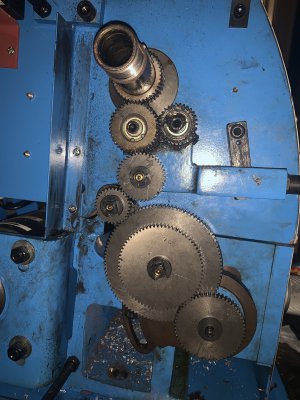

As mentioned, it's not unheard of for charts to be wrong. This may help:

littlemachineshop.com

littlemachineshop.com

It's well worth investing a little time in truly understanding it all from first principals, though, then the calculators (or indeed charts) are much easier to use and understand.

Hope you're happily threading the correct pitch soon!

Change Gears for Threading

This calculator determines the correct change gears for any thread pitch. Works for all mini lathes and HiTorque Bench Lathes.

It's well worth investing a little time in truly understanding it all from first principals, though, then the calculators (or indeed charts) are much easier to use and understand.

Hope you're happily threading the correct pitch soon!