- Joined

- Jul 5, 2014

- Messages

- 2,776

You guys have given me a lot to think about.

Here are pics of the housings. First pic shows the hole for the cable drive. Until recently I didn't think the ford housings were worth keeping. Then a potential customer told me they are going for $500 on ebay if you can find them. The non cable drive ones are a dime a dozen. So the hope is I can modify the housing in the second pic. The sleeve will be half out of the housing unlike other ones I do.

The customer is sending me a couple of housings to work with. Hopefully the will be here soon.

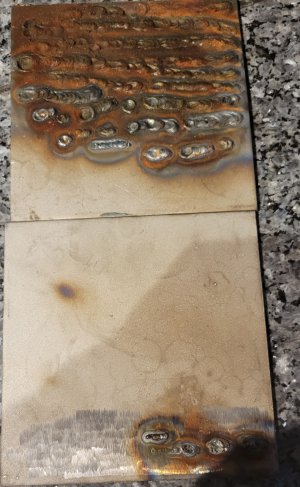

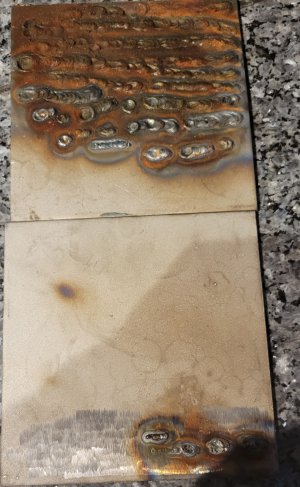

Last pic is from tonights welding class. Tonight we had a third instructor. First injstructor David was there one night and it was just orientation. Second night was Natasha. She isn't very helpful. For 2 nights she didn't even see me. Tonight Nathan was there and he actually came over to see how I was doing (terrible) and he tried to use the welder. He did worse than I'm doing. He welds for a living but not doing tig. He said when he has used tig is was super easy. He thinks there is something wrong with the welder. I think there is a morning class, then an afternoon class, then a night class all using the same equipment and they all change the settings on the machine. Then I come along and have no clue other setting the electrode to negitve and changing the amp settings about the welder.

He said he is going to check with his boss and see what he says about it. Tonight was a waste and I'm upset about it because they need to have an instructor teaching the class that knows what he's doing. It's not Nathans fault, as far as I can tell he was a last minute fill in. I asked him about what happened to David and no one will say. I hope he comes back, but I'm not sure if I'll take the class again considering what happened tonight.

Top plate is all me except for the one weld the bottom two rows. Second plate is all Nathan. I gave up and left before the class was over. I don't understand why everything turned brown.

Here are pics of the housings. First pic shows the hole for the cable drive. Until recently I didn't think the ford housings were worth keeping. Then a potential customer told me they are going for $500 on ebay if you can find them. The non cable drive ones are a dime a dozen. So the hope is I can modify the housing in the second pic. The sleeve will be half out of the housing unlike other ones I do.

The customer is sending me a couple of housings to work with. Hopefully the will be here soon.

Last pic is from tonights welding class. Tonight we had a third instructor. First injstructor David was there one night and it was just orientation. Second night was Natasha. She isn't very helpful. For 2 nights she didn't even see me. Tonight Nathan was there and he actually came over to see how I was doing (terrible) and he tried to use the welder. He did worse than I'm doing. He welds for a living but not doing tig. He said when he has used tig is was super easy. He thinks there is something wrong with the welder. I think there is a morning class, then an afternoon class, then a night class all using the same equipment and they all change the settings on the machine. Then I come along and have no clue other setting the electrode to negitve and changing the amp settings about the welder.

He said he is going to check with his boss and see what he says about it. Tonight was a waste and I'm upset about it because they need to have an instructor teaching the class that knows what he's doing. It's not Nathans fault, as far as I can tell he was a last minute fill in. I asked him about what happened to David and no one will say. I hope he comes back, but I'm not sure if I'll take the class again considering what happened tonight.

Top plate is all me except for the one weld the bottom two rows. Second plate is all Nathan. I gave up and left before the class was over. I don't understand why everything turned brown.