- Joined

- Dec 12, 2011

- Messages

- 132

Mike,

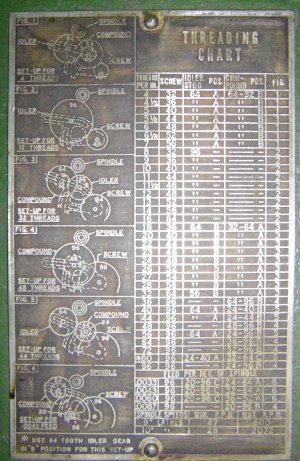

If you don't already have them, you should go to Downloads/Atlas... and get the two Atlas Lathe 10F Series files that I just uploaded. They should match your machine.

The 10" through 10D/E had no spindle stud compound gear. And came with two 96T gears. The highest tooth count in the 10F and most 12" is 64T. And I think that if you remove the left 64T gear from your banjo, you will see that your banjo does not match Wayne's.

Also, not that it matters much, the 32/16 compound gear shown on your chart close to but not engaging the spindle gear is on the tumbler and is farther away from the spindle gear than on your machine. There are one or two (FWD or REV) more gears between it and the spindle gear.

Robert D.

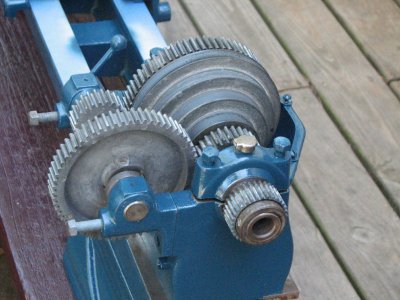

Yes mine does not have this stud and gears but has a F\R gearbox at the head end of the leadscrew. Of interest I just came upon the pictures of the 1933 9" Metalcraft built by Atlas and it is pretty much Identical to my 10" other then the headstock and feet. Of particular interest to me was the picture of the inside of the reverse gearbox .When I got my lathe it was missing the center shift collar and it was not possible to find one to match my gears so I had to make one (the first thing I ever made on a lathe). here are pics of the gearbox and the part I had to make. I still haven't found one for sale anywhere .

Wayne F