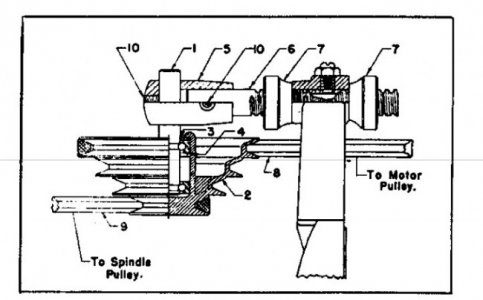

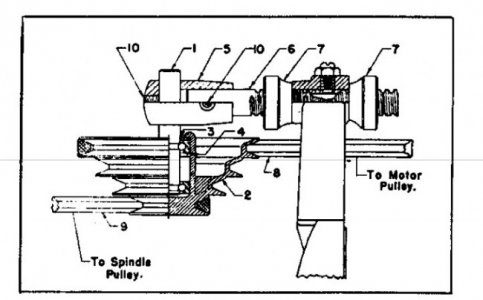

As I'm learning machining basics, i see more need for slower speed on my drill press (1930's Walker Turner 15" floor model). I wound up with a trashed out slow speed attachment that needed some work.

(as found)

There were two basic problems - the smallest diameter pulley was simply missing - apparently worn off, and the bearings were done.

There were two types of this attachment and i wound up with the older, non-serviceable type where the bearings are integral to the shaft. The inner race was actually ground onto the shaft and the bearings were assembled onto it. Hmmmm. And, to make things more interesting, there was an internal snap ring on the I.D. of the pulley, in between the two bearings. You can't press the shaft / bearing assembly out through either end of the pulley.

this is as far as i could get the shaft/bearing assy out of the pulley

But i'm stubborn.

Since one bearing was free of the pulley, i cut it off with my rotary tool. Then, i pressed the shaft / remaining bearing out the other side of the pulley bore. Finally, i removed the internal snap ring. Disassembled and partially destroyed.

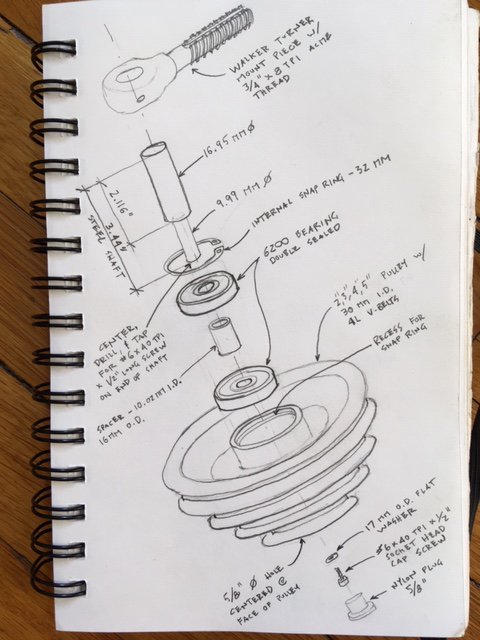

I turned a new shaft with a reduced diameter section to press new bearings on (with a spacer in between them). I drilled and tapped this smaller end of the shaft and fixed the bearings to the shaft with a washer / socket head cap screw.

Then came fixing the pulley. It originally was a 5", 4", 3", 2" step pulley. The 2" section was missing, and the 3" section was too worn to use any more. My Dad happened to have a 3", 2" step pulley, so with a little lathe work and some JB Weld they soon became one.

Then i turned the assembly on the lathe, taking light cuts - just enough to true it all up. One last cut on the I.D. of the pulley for a new snap ring to hold it all in place, and it all went together nicely.

Basically, i copied how the newer version of the Walker Turner slow speed attachment is made. Now, at least, it's serviceable when the bearings wear out. I'm not posting this to brag (though i'm happy with how it came out). I do hope this might help someone else who finds themself in the same situation.

Now i just need to mount it on the press and put it to work.

paulh

(as found)

There were two basic problems - the smallest diameter pulley was simply missing - apparently worn off, and the bearings were done.

There were two types of this attachment and i wound up with the older, non-serviceable type where the bearings are integral to the shaft. The inner race was actually ground onto the shaft and the bearings were assembled onto it. Hmmmm. And, to make things more interesting, there was an internal snap ring on the I.D. of the pulley, in between the two bearings. You can't press the shaft / bearing assembly out through either end of the pulley.

this is as far as i could get the shaft/bearing assy out of the pulley

But i'm stubborn.

Since one bearing was free of the pulley, i cut it off with my rotary tool. Then, i pressed the shaft / remaining bearing out the other side of the pulley bore. Finally, i removed the internal snap ring. Disassembled and partially destroyed.

I turned a new shaft with a reduced diameter section to press new bearings on (with a spacer in between them). I drilled and tapped this smaller end of the shaft and fixed the bearings to the shaft with a washer / socket head cap screw.

Then came fixing the pulley. It originally was a 5", 4", 3", 2" step pulley. The 2" section was missing, and the 3" section was too worn to use any more. My Dad happened to have a 3", 2" step pulley, so with a little lathe work and some JB Weld they soon became one.

Then i turned the assembly on the lathe, taking light cuts - just enough to true it all up. One last cut on the I.D. of the pulley for a new snap ring to hold it all in place, and it all went together nicely.

Basically, i copied how the newer version of the Walker Turner slow speed attachment is made. Now, at least, it's serviceable when the bearings wear out. I'm not posting this to brag (though i'm happy with how it came out). I do hope this might help someone else who finds themself in the same situation.

Now i just need to mount it on the press and put it to work.

paulh