Finished refurbishment on my second heavy 10. This one unlike my other has a 1-1/2hp 3ph motor on it. I would like a simple to use and program vfd for it. So if you can recommend one and tell me why you like it, I would appreciate that. Thanks.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VFD for South Bend 10L Recommendation

- Thread starter clm1899

- Start date

My favorite brand is Hitachi, Automation Direct has some pretty good ones too. Several other brands are good, I have less experience with them. All are easy to use once set up. "Easy to program" is not something I would claim about any, "easy once you know how" perhaps.

- Joined

- Sep 28, 2022

- Messages

- 141

I’ll show you my Heavy 10 setup that I’ve had for quite a few years and have been happy with. I found a surplused 2 hp Mitsubishi motor (1,725 RPM, 3-phase.) The Lenze drive is either 2 or 3 hp – I can’t remember. This drive can run either single-phase or three-phase input. I don’t run braking resistors as I’ve found it isn’t really necessary on the Southbend. The Lenze was easy to program and has proven to be very reliable. I’ve also found that using the larger motor shiv and running the flat belt on its slowest setting is pretty much ideal for this configuration. The machine has more than enough power to slip the belt even at the lowest frequency I run.

I’ve posted some pictures of the machine at full RPM and minimum RPM, and at full back gear RPM and minimum RPM in this configuration.

I added a little auxiliary fan in the bottom and a push button manual motor starter for a power disconnect. All the controls are in the little box that’s up front. I’ve also included a picture of the collet tray I made which makes use of some space that wasn’t used much before.

The following two are minimum and maximum in open belt and 20 hz minimum and 110 hz max. If I want the 1,400 RPM max, it is just one move of the flat belt.

The following two are minimum and maximum in full back gear.

I’ve posted some pictures of the machine at full RPM and minimum RPM, and at full back gear RPM and minimum RPM in this configuration.

I added a little auxiliary fan in the bottom and a push button manual motor starter for a power disconnect. All the controls are in the little box that’s up front. I’ve also included a picture of the collet tray I made which makes use of some space that wasn’t used much before.

The following two are minimum and maximum in open belt and 20 hz minimum and 110 hz max. If I want the 1,400 RPM max, it is just one move of the flat belt.

The following two are minimum and maximum in full back gear.

- Joined

- Jun 12, 2014

- Messages

- 4,810

DURApulse GS20 series are simple and easy to program, well you need to understand the parameters to some degree. Well made VFD with readable instructions, good set of programming parameters, supports an external braking resistor if needed, good technical support, etc. I have done a few installs with this model, the computer software is easy to use if you want to go that route. The Teco L510 which is often used for mills or simple VFD setups is more expensive these days, does not support external braking resistor and has a less feature rich parameters. Hitachi WJ200 is a solid workhorse, but an additional $100 over the GS21-22P0, they both do the same thing. These are the entry level VFD's that I often use, you also need to consider on the lathe as to the run controls, 2 wire or 3 wire control, jog, fast or E-Stop, etc. If you do not have a thread on chuck mount then I would suggest adding a braking resistor for faster stops.

GS21-22P0 DURApulse GS20 series AC general purpose drive, enclosed, 230 VAC, 2hp with 1-phase input

www.driveswarehouse.com

www.driveswarehouse.com

GS21-22P0 DURApulse GS20 series AC general purpose drive, enclosed, 230 VAC, 2hp with 1-phase input

WJ200-015SF

- Joined

- Jan 1, 2018

- Messages

- 1,156

I have a Hitachi WJ200 on my 13" Southbend lathe. It will do pretty much anything you can dream up for a VFD.

I have a 10hp Huanyang VFD on my 7.5hp radial arm saw. The Huanyang is MUCH more simplistic and took about 1/4 the time to figure out how to program. I am sticking with Huanyang for now on. It is so much easier to program and a fraction of the price of the Hitachi's.

I have a 10hp Huanyang VFD on my 7.5hp radial arm saw. The Huanyang is MUCH more simplistic and took about 1/4 the time to figure out how to program. I am sticking with Huanyang for now on. It is so much easier to program and a fraction of the price of the Hitachi's.

- Joined

- May 23, 2017

- Messages

- 109

If you want high torque at low motor RPM you want a sensorless vector drive type VFD. The low cost Huangang (and other low cost imports) are scalar type drives and the motor will stall out at low RPMs.

Mitsubishi has sold off obsolete models and sellers on eBay have them at very low cost. The D700 series, you want the D720 for 200 volt class, for 240 volt input.

This is a 1.5Kw capable unit; FR-D700 FR-D720-070-W1

You can download the pdf. I was never able to figure out the "W1", as this is typically "NA" for north america. And sellers could not answer that either. I assume it's a special software version. But there are many sellers with this model available on eBay. Search for D720, then select the model that will drive your motor size. Lots of .1KW, don't know what those are used for. These drives are sold for 3 phase input, but they work on single phase, as the default is no monitoring of loss of input phase.

You can download the pdf. I was never able to figure out the "W1", as this is typically "NA" for north america. And sellers could not answer that either. I assume it's a special software version. But there are many sellers with this model available on eBay. Search for D720, then select the model that will drive your motor size. Lots of .1KW, don't know what those are used for. These drives are sold for 3 phase input, but they work on single phase, as the default is no monitoring of loss of input phase.

Mitsubishi has sold off obsolete models and sellers on eBay have them at very low cost. The D700 series, you want the D720 for 200 volt class, for 240 volt input.

This is a 1.5Kw capable unit; FR-D700 FR-D720-070-W1

MITSUBISHI D700 VFD FR-D700 FR-D720-070-W1 Variable Frequency Drive NEW IN BOX | eBay

Mitsubishi Electric FR-D720-070-w1 New in Box T AC drive, Variable frequency, 2HP, 3-phase, 240v AC Input, 50/60 HZ, 2 40 VAC output,, 0.2-400hz, IP20 enclosure.

www.ebay.com

- Joined

- Jan 1, 2018

- Messages

- 1,156

My Huanyang VFD is a sensorless vector VFD.

The expensive brand name VFD's use proprietary (expensive) control logic chips with all sorts of great features (USB programmable is one of my favorite) and I would hope top end power transistors. There are some generic VFD control logic chips (I "THINK" TI makes at least one VFD MCU) that are used in the generic VFD's. From what I have seen the generic VFD's have more than enough complexity for simple forward / reverse, soft start, braking. jog, etc. control of a home hobby lathe.

If I was paying a guy $40/hr to run a lathe I certainly would invest in a top end drive. For my home shop it seems like over kill to me. I could buy a VFD and two spares and still come out ahead while still having all the controls I would get from a Hitachi.

I own multiple Hitachi, Fujitsu and Teco VFD's. The Huanyang VFD is my first generic Chinese VFD. I regret the money I spent on (and many hours I spent programming) the expensive VFD's. But this is just me. Everyone has their own priorities and is free to make their own choices.

The expensive brand name VFD's use proprietary (expensive) control logic chips with all sorts of great features (USB programmable is one of my favorite) and I would hope top end power transistors. There are some generic VFD control logic chips (I "THINK" TI makes at least one VFD MCU) that are used in the generic VFD's. From what I have seen the generic VFD's have more than enough complexity for simple forward / reverse, soft start, braking. jog, etc. control of a home hobby lathe.

If I was paying a guy $40/hr to run a lathe I certainly would invest in a top end drive. For my home shop it seems like over kill to me. I could buy a VFD and two spares and still come out ahead while still having all the controls I would get from a Hitachi.

I own multiple Hitachi, Fujitsu and Teco VFD's. The Huanyang VFD is my first generic Chinese VFD. I regret the money I spent on (and many hours I spent programming) the expensive VFD's. But this is just me. Everyone has their own priorities and is free to make their own choices.

Last edited:

- Joined

- Dec 10, 2023

- Messages

- 68

The WSJ200 linked/pictured above looks very much like the TECO FM50 I had on a SB9A (2004), on my pre-WWII Rivett 1020 (avatar) (2007- ) and currently have on my Select 6x26 knee mill (since 2005). I also installed one on a Bridgeport about 8 yrs ago. Pretty easy to wire and program. I wired it with remote speed control pot and DPDT toggle switch for Forward/Off/Reverse operation, so after initial setup I never touch the VFD, just those controls.

Attachments

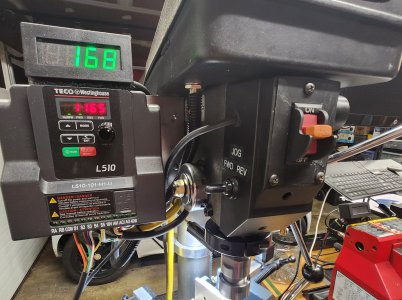

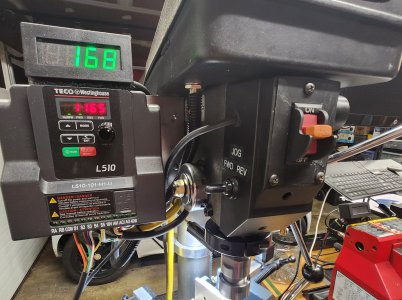

I've had excellent service from the Teco unit which controls my drill press 3-phase motor. I added a momentary toggle on the left to control jogging, real handy for tapping threads, and a 3-position switch on the right to control fwd-off-rev. It wasn't the easiest user interface I've ever come across, once I figured it out, it was easy-peasy. Telephone technical support was outstanding!