- Joined

- Aug 26, 2013

- Messages

- 167

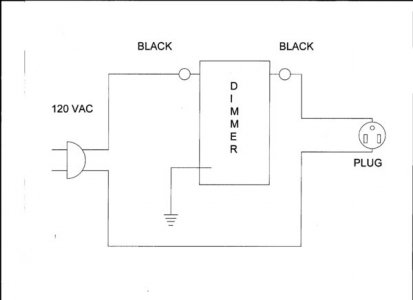

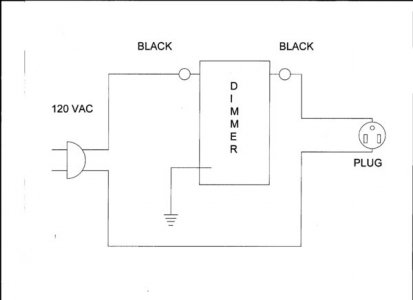

I know this may be the wrong forum for this but, I didn't know where else to get an answer. Is this a safe

schematic? Want to use it to control power ( how hot it gets ) of s soldering iron. I will be useing a wall socket to provide 120 VAC and then pluging in the soldering iron at the other end. The dimmer has an off switch.

schematic? Want to use it to control power ( how hot it gets ) of s soldering iron. I will be useing a wall socket to provide 120 VAC and then pluging in the soldering iron at the other end. The dimmer has an off switch.