- Joined

- Feb 9, 2017

- Messages

- 5,255

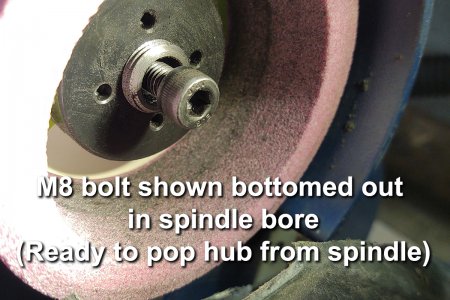

Yup, I’m familiar with tapered fits and whacked end of the bolt style puller hard enough the end of the shaft got slightly buggered. Must be kinda soft. That’s why I paused to make sure I’m not forgetting something. Rather than use a bolt puller for this first time to break it loose I think I’m going to make a special bolt with shoulder to save to end of the shaft and use my Chrysler hub puller and put the whack to it. And hope I don’t screw the whole thing up.After getting the bolt really tight a rap with a hammer is sometimes required. ATV clutches and generator rotors come off the same way.