- Joined

- Oct 13, 2012

- Messages

- 175

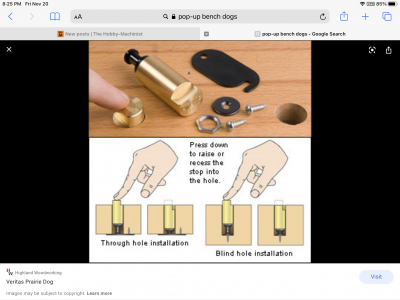

I'm looking for work stops I can install in the surface my CNC router work table that you give a twist and they pop up. Press down and twist and they lock below the surface of the work table. Anyone seen these, either for wood working or machining? I would use them for aligning the work on the CNC table to the axis/origin and if designed right might even be used for work holding by biting into the base of the stock.

-Freeman

-Freeman