-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turning my garage into my little machine shop

- Thread starter Brento

- Start date

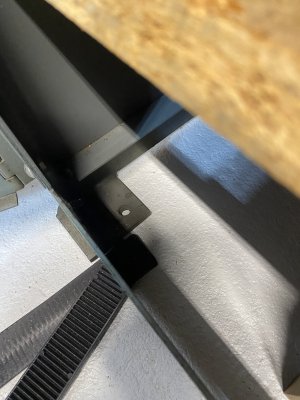

I can get a picture later. idk if im gonna get a pad under the mill feet unless i pick it up again and i dont really want to but i can maybe tilt it with a prybar or something to slide something under. My thought was at first a long set screw with maybe a soft end piece so it would not dig into the ground as much. In the picture i send you later i will also show you that i am stuck with a height requirement as well bc inside the cabinet i dont want to sit to high and make the bas uneven

This is one of the feet inside the cabinet. It was also brought to my attention from a friend of mine that with the mill weighing in at 720+ and only a 1/4-3/8" of thread that it may not be strong enough. Which leads me to your idea. Maybe make a foot and use a 1/2 threaded rod with two nuts as you said. It will be on of my projects. But in order to do that project i need to level the mill out a little so in the mean time i am going to use these shims to make it sturdy. The feet will be my first project after i make the Tnut for my lathe post. How thick should the foot be? I am thinking of using a plastic block on the bottom of the foot i make to give a little cushion to not beat up the floors perhaps.

Attachments

- Joined

- Nov 14, 2016

- Messages

- 3,006

My understanding is levelling a mill is more of a it can be nice thing than something that really matters. I guess there are times where being able to put a level on your work can be useful, oil and parts won't run down to the low end, but it seems like it would have to be pretty out of level for that to be an issue.

Mine is pretty level, but not perfectly level and I haven't found it to cause any issues any issues worth raising the mill to put leveling feet under it (only real issue I've found is knowing it isn't perfectly level ).

).

Mine came with a set of DIY leveling feet made from 3/8" carriage bolts, but I forget to install them before reassembling the mill, and can't be bothered to raise the mill to install them. The weight shouldn't be an issue for 1/4" or 3/8" rod as it is divided by 4 so less than 200lbs ea, and the rods of the feet are only going to be about 1" long and the weight is directly over the top of them, where the rods will be their strongest.

Mine is pretty level, but not perfectly level and I haven't found it to cause any issues any issues worth raising the mill to put leveling feet under it (only real issue I've found is knowing it isn't perfectly level

Mine came with a set of DIY leveling feet made from 3/8" carriage bolts, but I forget to install them before reassembling the mill, and can't be bothered to raise the mill to install them. The weight shouldn't be an issue for 1/4" or 3/8" rod as it is divided by 4 so less than 200lbs ea, and the rods of the feet are only going to be about 1" long and the weight is directly over the top of them, where the rods will be their strongest.

@Aaron_W the thickness of the existing foot is only 3/8 of an inch. But i will make a better foot to work with in the future.

Tonight i lubricated my mill and trammed the head in i am out a though on the Y but to adjust that is not going to be the easiest so i will live with it for now. In the future i will shim the ram base on the head to maybe bring it in a half a thou. I set up my new screwless vice as my bigger vice that came with the mill needs to be cleaned and gone through. The fixed jaw is out about .0005-.0007 up and down. I checked the bottom oh the jaws and that was a half a thou at most along the whole length of the vice. Tmr i need to drill some 9/16 holes to fit my hold downs that came with the vice over my hardware. Then to mill my T slot for my lathe. I also screwed up and had to reorder a new MT2-ER20 holder bc the one i order a year or so ago was M10 threads. Imagine my face when i found that out! After tmr i believe my journey to make my shop will be complete! If everyone enjoys the updates then i will revive and continue next time i do an addition to the shop. I know i have a Granite top that i may use as my surface plate but i will have to put it up on the mill and see what my readings are on it.

Until next time i say this shop is done after about 80 hours of Labor and almost 1200$ i say this was a great and fun journey. I only hope now that i can get some more projects on the list to do and maybe a few paying jobs!

Tonight i lubricated my mill and trammed the head in i am out a though on the Y but to adjust that is not going to be the easiest so i will live with it for now. In the future i will shim the ram base on the head to maybe bring it in a half a thou. I set up my new screwless vice as my bigger vice that came with the mill needs to be cleaned and gone through. The fixed jaw is out about .0005-.0007 up and down. I checked the bottom oh the jaws and that was a half a thou at most along the whole length of the vice. Tmr i need to drill some 9/16 holes to fit my hold downs that came with the vice over my hardware. Then to mill my T slot for my lathe. I also screwed up and had to reorder a new MT2-ER20 holder bc the one i order a year or so ago was M10 threads. Imagine my face when i found that out! After tmr i believe my journey to make my shop will be complete! If everyone enjoys the updates then i will revive and continue next time i do an addition to the shop. I know i have a Granite top that i may use as my surface plate but i will have to put it up on the mill and see what my readings are on it.

Until next time i say this shop is done after about 80 hours of Labor and almost 1200$ i say this was a great and fun journey. I only hope now that i can get some more projects on the list to do and maybe a few paying jobs!