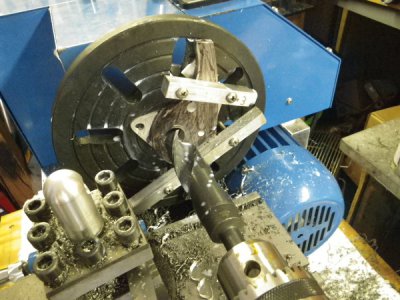

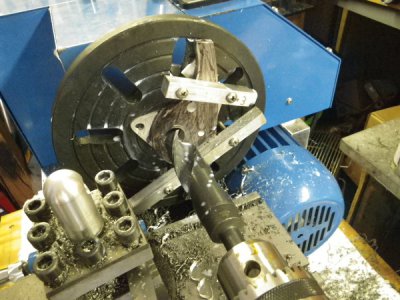

Andrew requested a new ignition switch holder for a fork change he is contemplating on BMW F650 GS. I told him I would try to get it together for him. After scaling the drawing, drilling the 8mm and 6mm holes in the drill press and shaping the piece it was time to bore the 30mm ignition cylinder hole. My largest bit is 1" or 25.4mm so after a series of stepped up hole diameters it was time to bore out the last 5mm.

The oddly shaped part required half a day of thinking and beer contemplation to get it set on the face plate.

Here are some shots from Flatistan Fabrication, makers of exemplary F650 farkles:

The oddly shaped part required half a day of thinking and beer contemplation to get it set on the face plate.

Here are some shots from Flatistan Fabrication, makers of exemplary F650 farkles: