Hello all. I've been fortunate enough to just win an auction for a lovely looking b&s 6x12 surface grinder. Appears to have a hydraulic feed? I'm going to pick it up next week and have been struggling to find any moving instructions for these machines. Is there anything that should be removed before bouncing down the highway? Fluid drained? Any specific lift points that are preferred? Thanks for helping out a complete newbie in this area.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Transporting a Boyar and Shultz 612-H

- Thread starter mx6er2587

- Start date

{ Choice of lots: 118 } 6" X 12" BOYER-SCHULTZ MODEL 612-H HAND FEED SURFACE GRINDER; S/N HY-586

Lot 118 at Aerospace Parts Manufacturer from Cincinnati Industrial Auctioneers.

- Joined

- Mar 26, 2018

- Messages

- 8,410

You can probably find the a manual on www.vintagemachinery.org

They will have the suggested tie down-transport-lifting methods.

My Brown and Sharpe 6X18 is a heavy SG.

You are not supposed to strap across the table. It can cause damage.

Congratulations.

They will have the suggested tie down-transport-lifting methods.

My Brown and Sharpe 6X18 is a heavy SG.

You are not supposed to strap across the table. It can cause damage.

Congratulations.

- Joined

- Nov 26, 2017

- Messages

- 1,517

Nice looking unit, congratulations. Would love to find something like that out here.

Here is the link to the manual Jeff suggested above. http://www.vintagemachinery.org/pubs/detail.aspx?id=4860

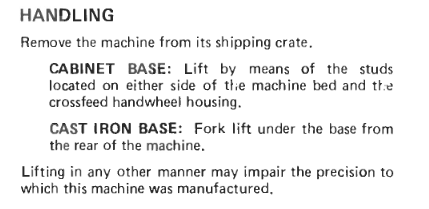

Here is the section regarding handling. It would appear as though there are studs used for lifting. Those would be your tie down points as well.

Here is the link to the manual Jeff suggested above. http://www.vintagemachinery.org/pubs/detail.aspx?id=4860

Here is the section regarding handling. It would appear as though there are studs used for lifting. Those would be your tie down points as well.

- Joined

- Feb 2, 2013

- Messages

- 3,628

You may wish to separate the hydraulic unit from the surface grinder before .

There are lift points (lifting studs) on the sides of the base.

The unit is not heavy, unless you have the cast iron base

You may wish to remove and invert the table for travel if the chuck is not installed.

If the chuck is present, it may be easier to transport with the table installed, just realize that the table will need to be lashed down to prevent movement.

a point to consider is to avoid putting pressure on the ends of the table to avoid deformation.

Congratulations on the new acquisition!

There are lift points (lifting studs) on the sides of the base.

The unit is not heavy, unless you have the cast iron base

You may wish to remove and invert the table for travel if the chuck is not installed.

If the chuck is present, it may be easier to transport with the table installed, just realize that the table will need to be lashed down to prevent movement.

a point to consider is to avoid putting pressure on the ends of the table to avoid deformation.

Congratulations on the new acquisition!

- Joined

- Jun 7, 2013

- Messages

- 10,105

This is a manual travel machine, there is no hydraulic unit. I think it would be best to remove the table for transport and transport it upside down, having first removed the chuck.You may wish to separate the hydraulic unit from the surface grinder before .

There are lift points (lifting studs) on the sides of the base.

The unit is not heavy, unless you have the cast iron base

You may wish to remove and invert the table for travel if the chuck is not installed.

If the chuck is present, it may be easier to transport with the table installed, just realize that the table will need to be lashed down to prevent movement.

a point to consider is to avoid putting pressure on the ends of the table to avoid deformation.

Congratulations on the new acquisition!

- Joined

- Jan 20, 2016

- Messages

- 173

They are supposed to have 4 bolts inside the cabinet that holds the top onto the cabinet. Make sure they are there. Leave the table on, lock in center of travel with the table stops. Crank the table all the way back under the wheel till near end of travel. Put a 6-12" chunk of 2x4 on table under the spindle, and lower spindle onto the 2x4. Remove the light, the spindle guard, and anything else left that can fall off.

Run a tiedown strap around the upright casting just above the spindle and tie it down to front of truck/trailer. Do that 3 more times, going to back, left, and right sides of truck/trailer. Won't move a bit!

If you need to lift it, put the forks under the 2 hex bars that stick out the sides, or wrap straps around the bars.

Run a tiedown strap around the upright casting just above the spindle and tie it down to front of truck/trailer. Do that 3 more times, going to back, left, and right sides of truck/trailer. Won't move a bit!

If you need to lift it, put the forks under the 2 hex bars that stick out the sides, or wrap straps around the bars.

- Joined

- Nov 26, 2015

- Messages

- 4,792

I see the post but no spark shoot. Check around for it. You can see what one is in this Ebay ad.

Boyar Schultz Challenger Deluxe 6" x 18" | eBay

6” x 18”Ceramax Walker Perm Mag Chuck. Before signing, remove the stretch film and inspect. Let us arrange your freight at the best rate possible.

www.ebay.com

- Joined

- Apr 14, 2014

- Messages

- 3,169

The description on the website does refer to it as a manual grinder. However if you enlarge the pictures #3 shows the product tag that says "Hydraulic Surface grinder 612-H. You can also see the directional change valve in pictures #4, #6, #7, and #8. Pictures #6and #7 also show what I believe is the pump on/off switch. However I don't see any hydraulic tank or pump. Every "hydraulic" unit I've seen has a stand alone pump/reservoir.This is a manual travel machine, there is no hydraulic unit. I think it would be best to remove the table for transport and transport it upside down, having first removed the chuck.

I'm thinking this unit was originally a hydraulic one, that was later stripped of the tank and pump and used as a manual unit.

Thanks for the help with this one all. Followed Grandpops procedure just about to the T to load. The machine did indeed have two large lifting studs on either side of the cast iron base of the grinder itself (not on the base). We picked it up easily with a lifting strap around the studs using a fork truck. Then just backed the trailer under the machine. Put a nice chunk of 4x4 between the chuck and the spindle to keep things from bouncing around. Getting it off the trailer once back home was a bit more difficult. Had to remove the chuck and table to shed some weight. Unbolt the base from the grinder while trying not to breath in 40 years of grinding dust and then essentially drag the grinder off its base with a hoist. After that I was able to put the base on a dolly and roll everything into the shop. The rub is I'm not sure I'll be able to get enough height on the hoist to get the machine back on the base. Oh well, I'll figure something out.

As for the machine itself its in great condition. Everything turns nice and smooth and its obvious this machine had been put to work fairly recently. The table ways look immaculate and the spark shoot was still attached to the machine. The air handler definitely needs a thorough cleaning. Its absolutely a hydraulic feed unit but is missing its pump and tank as projectnut has pointed out. I'm hoping I can rig up a replacement pump based on the specs in the owners manual. If that doesn't work out I won't be too heartbroken as I had only been looking for a manual unit.

Looking forward to getting her up and running in the next couple weeks. Also picked up a South bend heavy 10 at the auction so I now have some decisions to make as I've been told by the wife that I'm over my lathe limit!

As for the machine itself its in great condition. Everything turns nice and smooth and its obvious this machine had been put to work fairly recently. The table ways look immaculate and the spark shoot was still attached to the machine. The air handler definitely needs a thorough cleaning. Its absolutely a hydraulic feed unit but is missing its pump and tank as projectnut has pointed out. I'm hoping I can rig up a replacement pump based on the specs in the owners manual. If that doesn't work out I won't be too heartbroken as I had only been looking for a manual unit.

Looking forward to getting her up and running in the next couple weeks. Also picked up a South bend heavy 10 at the auction so I now have some decisions to make as I've been told by the wife that I'm over my lathe limit!