I was looking into details of How to grind D-bits (single lip cutters) and part of that led me to a statement that was something like “…similar to a Toolmakers reamer where a single 20 degree cutting edge is ground and stoned…”

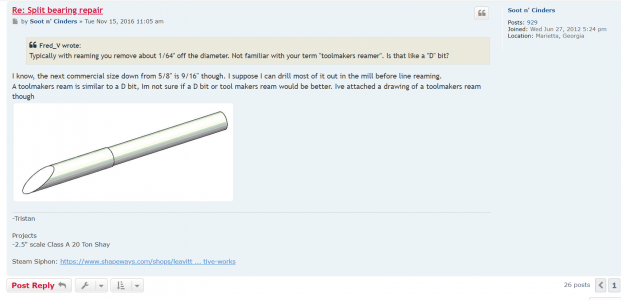

Does anyone know what this reamer might look like? It proports to make an exceptionally accurate and smooth reamed hole with a home made reamer.

Is it just grinding a solid blank on a 20 degree angle and then pushing that into an underside drilled hole?

I got the feeling this is an old school technique, but one that might be a nice option when u don’t want to buy an expensive reamer maybe for an odd sized hole.

Anyone heard of this? I especially would like to see a picture.

Does anyone know what this reamer might look like? It proports to make an exceptionally accurate and smooth reamed hole with a home made reamer.

Is it just grinding a solid blank on a 20 degree angle and then pushing that into an underside drilled hole?

I got the feeling this is an old school technique, but one that might be a nice option when u don’t want to buy an expensive reamer maybe for an odd sized hole.

Anyone heard of this? I especially would like to see a picture.