- Joined

- Jun 18, 2020

- Messages

- 31

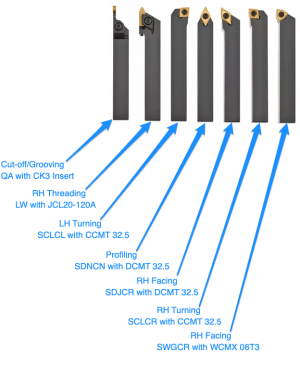

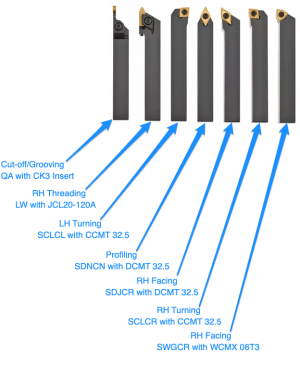

Can anyone verify that I have label the below tooling correctly along with its function? Can any of the other tooling be used for threading besides the RH threading (second from the left) tool?

Can anyone tell me they type of tooling below (left to right? This is the Grizzly H5687 set but they don't tell what each one is.

Can anyone tell me they type of tooling below (left to right? This is the Grizzly H5687 set but they don't tell what each one is.