- Joined

- Oct 8, 2013

- Messages

- 58

OK... I took apart this Sheldon 10", moved it into the basement (with help from Dave), got it cleaned up and painted, and put back together. This is my first actual tool, other than drill press/welders/plasma cutter/woodworking tools... first real tool.

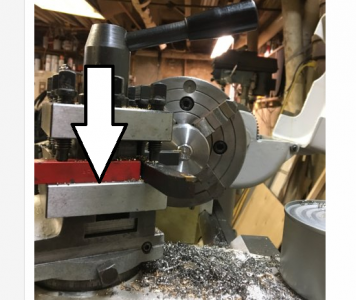

The friend who helped me pick it up and get it to my house generously gave me a tool post he was not using (NOS). I was able to grind/sand the clamp part to fit my compound... great! I got some import indexable tools, one (HSS?) cutting tool was in the drawer, along with one (harbor freight?) cutting tool. At least some tooling so that I can play around and learn...

And... all of the cutting edges sit higher than the center of the work!? I'd say this tool post is too large for this lathe, however... I really cannot (yet) afford another, so...

it seems that my only options are find smaller cutting tools, or find a way to mill down the thickness of the base of this tool post, right? or is there something else that I'm missing?

Thanks,

Steve

The friend who helped me pick it up and get it to my house generously gave me a tool post he was not using (NOS). I was able to grind/sand the clamp part to fit my compound... great! I got some import indexable tools, one (HSS?) cutting tool was in the drawer, along with one (harbor freight?) cutting tool. At least some tooling so that I can play around and learn...

And... all of the cutting edges sit higher than the center of the work!? I'd say this tool post is too large for this lathe, however... I really cannot (yet) afford another, so...

it seems that my only options are find smaller cutting tools, or find a way to mill down the thickness of the base of this tool post, right? or is there something else that I'm missing?

Thanks,

Steve