Frankly, I watching with great anticipation. I don’t need a full size surface grinder. Sure, if I had a 1500 sf shop, I’d probably get a decent used one but I’m dealing with around a total of about 300 square feet between the two rooms of my shop. It’s really 200sf of 1/2 of a carport plus another room which is 7 x 20. The 7 x 20ft room really isn’t that much use for a shop machine.

Anyway, I’ve crammed in my major tools....lathes and mil plus a shaper which I really didn’t have room for but I saw it on Craigslist and the guy really wasn’t greedy at all. Paid 400.00 for it.

So...the only reason for my long above rant is that I’ve been working on adapting a shop made toolpost type grinder to the shaper. I figured that the shaper has the mass for the job....and other than the task of protecting grinding dust from shaper moving parts....if I can pull this off, it might be a valid project. Unfortunately....my first attempt just had too much vibration of the grinder so I’m working on adding a better designed support of the grinder shaft.

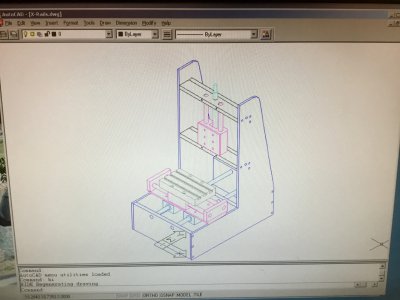

So...as I said in the first line....Watching with anticipation Frank. So far, I like your plan. The beauty of your project is I could fit this in the 7x20 room. FWIW....I was able to view your drawings using a downloaded DWG viewer app. It’s free on iPhone App Store

Anyway, I’ve crammed in my major tools....lathes and mil plus a shaper which I really didn’t have room for but I saw it on Craigslist and the guy really wasn’t greedy at all. Paid 400.00 for it.

So...the only reason for my long above rant is that I’ve been working on adapting a shop made toolpost type grinder to the shaper. I figured that the shaper has the mass for the job....and other than the task of protecting grinding dust from shaper moving parts....if I can pull this off, it might be a valid project. Unfortunately....my first attempt just had too much vibration of the grinder so I’m working on adding a better designed support of the grinder shaft.

So...as I said in the first line....Watching with anticipation Frank. So far, I like your plan. The beauty of your project is I could fit this in the 7x20 room. FWIW....I was able to view your drawings using a downloaded DWG viewer app. It’s free on iPhone App Store