- Joined

- Oct 7, 2020

- Messages

- 2,113

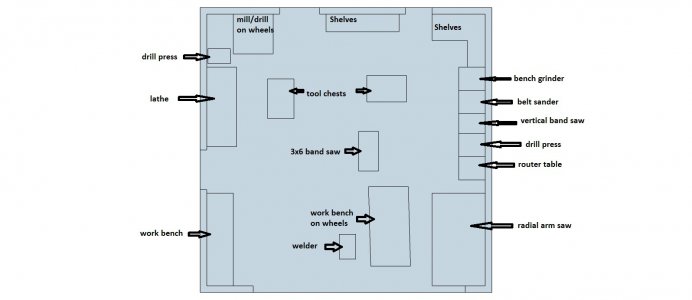

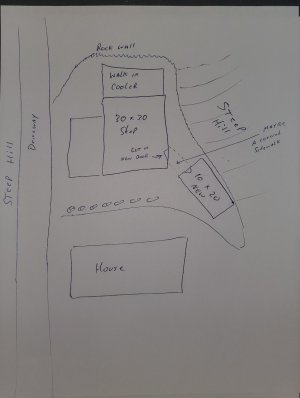

So I currently do not own any machine shop tools. But I have a plan! My current shop is 30'x30' that is full for the most part. I have a 200 Amp service feeding the shop, floor heat, air compressor, Mig, Tig and Stick welders, plasma cutter Oxy/acetylene torch and lots of other tools. All that, I plan on keeping the same and in the shop. My plan is to build another building 10'x20' just a few feed away maybe 10' to 15' but on the opposite side of the building from the power. I'm thinking at this point about installing a 100 amp service panel in the new building, but like I said rough guess 45' to 50' from the existing 200 amp service panel. I would like to have floor heat in the new building along with Air Conditioner those two things are the big hitters for AC power besides the lathe and mill. My plan for a lathe is a PM-1236 Precision and for the mill a PM-728VT.

Lots of things to think about but I think I can do it!

Lots of things to think about but I think I can do it!