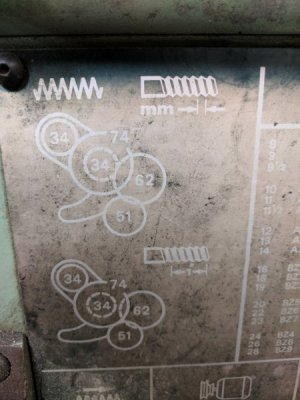

The 74 is meaningless for the imperial setup, it is only acting as an idler and does not change the ratio at all, only the direction. The gear ratio is from 34 to 51. You would need to use the AZ4 gear box setting (12 TPI), and then double the change gearing ratio to double the gearbox input speed, for instance, change the first drive gear from 34 to 68 teeth, if that is indeed possible on that lathe. You could also use the AZ2 gear setting and increase the existing change gearing by a ratio of 3:2, a 150% increase. That could be done by replacing the 34 tooth drive gear with a 51 tooth gear and leaving the existing 51 tooth gear for a 1:1 ratio. You could also use any two gears with the same tooth count to achieve that 1:1 ratio. Again, the center idler does not change anything unless set up for compound gearing. I assume you only have the four change gears shown in the two charts, and they alone will not do the job for a 6 pitch thread.