- Joined

- Oct 31, 2016

- Messages

- 2,649

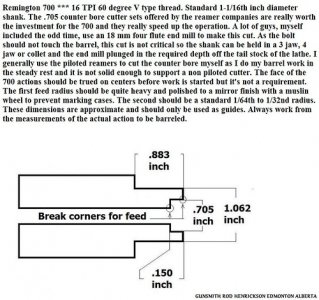

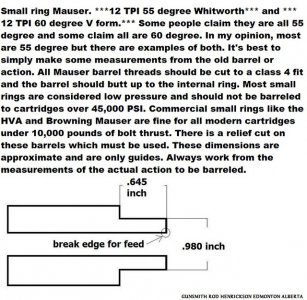

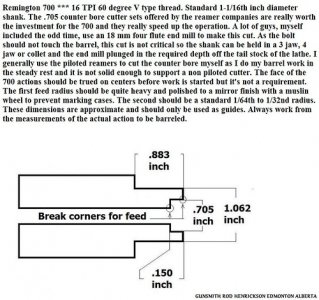

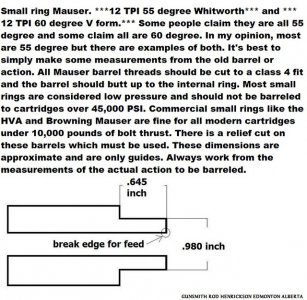

This is probably my dumb idea of the month or even the year. I have been planning to buy Green Mountain barrels for my mauser projects. Green Mountain has been sold out of the barrels I want for awhile. In cruising the net looking for other options I see lots of Remington 700 barrels for sale. All the way from dirt cheap to expensive. The Rem 700 is a 1.062" x 16 tpi. Curiosity got me checking to see what is the minor diameter of a 1.062 x 16 tpi. Turns out it is 0.9876" The OD on a small ring mauser is 0.980. Here are drawings of the 700 and mauser.

The 700 shank is longer than the mauser even after you shorten it to remove the indent. Turn the shank down to .980 and shorten it to .645. Cut the 12 tpi whitworth thread and do a slight touch up with a chamber reamer for head space. I would be done. I know getting a brand new barrel is better. I am thinking of other alternatives that won't break the bank.

The 700 shank is longer than the mauser even after you shorten it to remove the indent. Turn the shank down to .980 and shorten it to .645. Cut the 12 tpi whitworth thread and do a slight touch up with a chamber reamer for head space. I would be done. I know getting a brand new barrel is better. I am thinking of other alternatives that won't break the bank.