I've got a brand new tire valve that I want to thread into the bottom of a spent 100ml CO2 cylinder. If you look at the link, that brass nut screws down on the threaded shank of the valve compressing the rubber gasket against the wheel rim of a car or truck. In order to drill and tap the cylinder I need to know the drill and tap size, but I cannot find anything on common bolt charts. Once I have the information, I'll cut off the head of the valve, drill and tap the cylinder, and then screw the valve into the cylinder and lock it in w/ thread sealant and the nut.

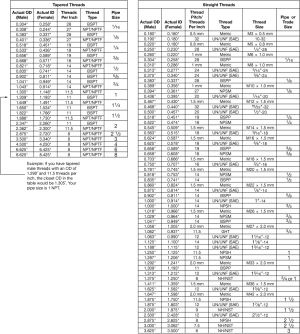

The threaded portion of the shank has an o.d. of 0.403", my calipers 'knife edge' is blunt and I am pretty sure both do not reach down to the bottom of the thread. This 'root' diameter is approximately 0.386" and there are 28 tpi. This tire valve is a standard TP500 type.

Can anyone ID this and tell me what drill and tap size to use?

My motorcycle air bag vest uses these 100ml canisters of CO2 to inflate the vest (Helite Turtle 2) when the lanyard attached to the bike is pulled out of the triggering socket. A heavy spring fires a pointed rod into the cartridge puncturing the seal and allowing the gas to flow into the air bag bladder, deploying the vest. The manufacturer is somewhat vague about how to adjust the vest so that it is not too tight or too loose when inflated. My idea (not very original, I'm afraid) is to put an air valve on a depleted cylinder, screw it into the trigger mechanism of the vest, and use a bicycle pump to inflate the bladder. At this point, everybody who owns a vest in the club to which I belong can adjust the straps so that the vest is secure but not eyeball popping tight.

The threaded portion of the shank has an o.d. of 0.403", my calipers 'knife edge' is blunt and I am pretty sure both do not reach down to the bottom of the thread. This 'root' diameter is approximately 0.386" and there are 28 tpi. This tire valve is a standard TP500 type.

Can anyone ID this and tell me what drill and tap size to use?

My motorcycle air bag vest uses these 100ml canisters of CO2 to inflate the vest (Helite Turtle 2) when the lanyard attached to the bike is pulled out of the triggering socket. A heavy spring fires a pointed rod into the cartridge puncturing the seal and allowing the gas to flow into the air bag bladder, deploying the vest. The manufacturer is somewhat vague about how to adjust the vest so that it is not too tight or too loose when inflated. My idea (not very original, I'm afraid) is to put an air valve on a depleted cylinder, screw it into the trigger mechanism of the vest, and use a bicycle pump to inflate the bladder. At this point, everybody who owns a vest in the club to which I belong can adjust the straps so that the vest is secure but not eyeball popping tight.