-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thread dial question!

- Thread starter Tr0nd

- Start date

Hello,

Are you referring to the Change Gear (for used to change the tread pitch) or the gear on the Tread Dial?

I've never seen a gear on the Thread Dial need to be changed.

If you could post some more information and Pictures of your lathe, it would be helpful to point you in the right direction.

Are you referring to the Change Gear (for used to change the tread pitch) or the gear on the Tread Dial?

I've never seen a gear on the Thread Dial need to be changed.

If you could post some more information and Pictures of your lathe, it would be helpful to point you in the right direction.

Just guessing but I suspect you are looking for change gears. W/O knowing what lathe you have it is not possible to help. Go back to the seller and /or manufacturer and see if they can help. Many such gears are spur gears and may be available from gear makers as stock items. In the US, Boston Gear is the go to. https://www.bostongear.com/-/media/...ns/p-1930-bg_engineering-info-spur-gears.ashx If your lathe is a Chinese made one, the same lathe may be sold under many different names and the gears available from several of them. But most of the sellers don't stock parts. There's always make your own if you have a mill.

- Joined

- Mar 21, 2018

- Messages

- 1,597

He's threading metric threads using the dial, which is possible, IF you have the correct type of dial and the necessary gears.

But Tr0nd, if you can't find the gears (actually, I think that these called worm wheel gears, not spurs), then you can still thread but not disengaging the carriage from the lead screw and reverse the lathe back to the start for each cut. This is the way an Imperial lathe cuts metric threads.

But Tr0nd, if you can't find the gears (actually, I think that these called worm wheel gears, not spurs), then you can still thread but not disengaging the carriage from the lead screw and reverse the lathe back to the start for each cut. This is the way an Imperial lathe cuts metric threads.

Yeah, sorry about that, I can do metric and imperial without changing gears, I do have to change to do trapezoidal/acme, but of course, those gears are nowhere to be found, so I'll have to make those one day. A day after I get some skills, might take a while

This is my lathe, I think it has a metric lead screw. And I'm in Norway, so I don't have to do much imperial anyways. So I might settle for the gear I have for the dial, but it takes forever to wait for it to come around now. Thought about trying to make one, but I noticed it wasn't straight cut, it's a slight angle on the teeth, so I'll give that thought a rest for now.

Thanks for answering guys!

This is my lathe, I think it has a metric lead screw. And I'm in Norway, so I don't have to do much imperial anyways. So I might settle for the gear I have for the dial, but it takes forever to wait for it to come around now. Thought about trying to make one, but I noticed it wasn't straight cut, it's a slight angle on the teeth, so I'll give that thought a rest for now.

Thanks for answering guys!

Last edited:

- Joined

- Feb 13, 2017

- Messages

- 2,138

I still have not come to terms with what gear you are refering to. What gets my attention is that you state that you can cut both metric and imperial threads without changing the gear. The leadscrew may be metric, it may be imperial, it doesn't matter. But either way, one or the other will require a change to cut the other thread. As in, if you have a metric lead screw, imperial threads must be cut without releasing the half nuts. If you have an imperial leadscrew, metric threads must be cut without releasing the half nuts. That is a given, as the two(metric or imperial) are not directly related. That 25.4 relationship is as close as it gets.

Assuming you are trying to find the gears listed in the original post, where 11, 13, 14, and 15 are listed, you can measure the existing gear(s) to determine what size is needed. They most likely will be metric (modulus) gears with 20 degree pressure angle. I would bet on them being modulus 1.5, but in reality that is just a wild guess. The best advice would be to take a mating gear to someone knowledable of gears and get their opinion. Someone that speaks your language. There are many nuances to English that do not translate well. There are many variables on gears and you need to know what they are to fit to them.

Then there are a pair that run together to do metric/imperial conversion. For smaller machines, these will be 127 and 120(or 100) teeth. For larger machines such as yours, they probably are internal to the gear box and may be a different number that gets close enough but not exact to 5 decimals. 127 is a prime number necessary for exact conversion. One of my machines uses 16DP gears, which is close to Modulus 1.5, almost. A 127 tooth gear in that pitch is quite large, being 150mm plus in diameter.

Then lastly, you speak of "waiting for the gear to come around" to the mark to start the next pass. This gear must not be changed. It is related to the pitch of the lead screw and varies depending on that. It is the one on the front apron that drives the rotating button for alignment to engage the half nuts. Waiting for that button to come around is a pain in the wazoo. It may only be used for cutting threads native to the lead screw. A metric leadscrew cutting metric threads for example. For the opposing thread, the half nuts must never be opened until complete. The machine is run in reverse with the half nuts closed to start another pass. That is noted in the first paragraph.

My (large) machine is very old, ca. 1950-52. A Craftsman (Atlas) 12x36 that is as old as I am. It is loose and creaky at best. When I am threading, I never release the half nuts, for Imperial or Metric. It allows me to maintain registration for the entire gear train from the spindle out. I took the indicator off the machine so it would not distract me, running the machine in reverse to start the next pass. I highly recommend doing this for anyone until they are conversant with a particular machine. It reduces mistakes. . . I have a smaller machine that is of Chinese origon. It has modulus 1.0 gears. The same details apply to both machines, varying only in specifics.

I apologize for being so verbose. You are having trouble expressing yourself in English and I truely do not understand what you are trying to describe. So I hit the major points and hope for the best.

Assuming you are trying to find the gears listed in the original post, where 11, 13, 14, and 15 are listed, you can measure the existing gear(s) to determine what size is needed. They most likely will be metric (modulus) gears with 20 degree pressure angle. I would bet on them being modulus 1.5, but in reality that is just a wild guess. The best advice would be to take a mating gear to someone knowledable of gears and get their opinion. Someone that speaks your language. There are many nuances to English that do not translate well. There are many variables on gears and you need to know what they are to fit to them.

Then there are a pair that run together to do metric/imperial conversion. For smaller machines, these will be 127 and 120(or 100) teeth. For larger machines such as yours, they probably are internal to the gear box and may be a different number that gets close enough but not exact to 5 decimals. 127 is a prime number necessary for exact conversion. One of my machines uses 16DP gears, which is close to Modulus 1.5, almost. A 127 tooth gear in that pitch is quite large, being 150mm plus in diameter.

Then lastly, you speak of "waiting for the gear to come around" to the mark to start the next pass. This gear must not be changed. It is related to the pitch of the lead screw and varies depending on that. It is the one on the front apron that drives the rotating button for alignment to engage the half nuts. Waiting for that button to come around is a pain in the wazoo. It may only be used for cutting threads native to the lead screw. A metric leadscrew cutting metric threads for example. For the opposing thread, the half nuts must never be opened until complete. The machine is run in reverse with the half nuts closed to start another pass. That is noted in the first paragraph.

My (large) machine is very old, ca. 1950-52. A Craftsman (Atlas) 12x36 that is as old as I am. It is loose and creaky at best. When I am threading, I never release the half nuts, for Imperial or Metric. It allows me to maintain registration for the entire gear train from the spindle out. I took the indicator off the machine so it would not distract me, running the machine in reverse to start the next pass. I highly recommend doing this for anyone until they are conversant with a particular machine. It reduces mistakes. . . I have a smaller machine that is of Chinese origon. It has modulus 1.0 gears. The same details apply to both machines, varying only in specifics.

I apologize for being so verbose. You are having trouble expressing yourself in English and I truely do not understand what you are trying to describe. So I hit the major points and hope for the best.

Bi11 Hudson

- Joined

- Mar 21, 2018

- Messages

- 1,597

I still have not come to terms with what gear you are refering to...

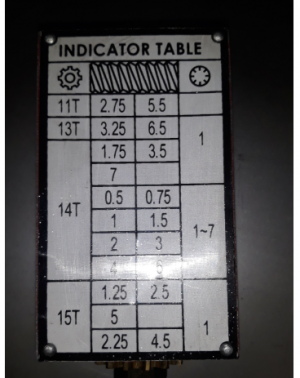

He's referring to the gears on his thread dial. A METRIC thread dial has various gears that allow for spindle/leadscrew syncing so that they can be cut by releasing the half-nut, just like Imperial threads. His chart shows gears of 11, 13, 14 and 15 teeth which are changed depending on the pitch that you want to cut. He says that he only received the 15 tooth gear, which limits him to the pitches that he can cut using the half-nut release method (see chart in post #1).

A METRIC leadscrew can cut both metric and Imperial threads, just as an Imperial leadscrew can cut both Imperial and metric threads IF you have the correct gearing in the HEAD of the lathe. Regardless of the leadscrew, a metric thread requires a special thread dial (which he has) to be able to use the half-nut method of cutting the threads.

- Joined

- Dec 12, 2016

- Messages

- 495

I have never heard of changing the gear on the thread dial. But if doing metric threads on an imperial leadscrew or vice verse you generally cannot release the half nuts, to the thread dial is not needed in that case. (I have seen a trick to releasing the half nuts but won't get into that here).

Attached is a picture of a typical thread dial, so we are talking about the same thing.

Attached is a picture of a typical thread dial, so we are talking about the same thing.

Attachments

Well I learned something new..... Having never worked on a "True Metric" lathe, I was unaware (at least some) do require different gears for the Threading Dial. Below is an article that describes why.

"As metric threads are specified as a pitch, and not generally fractions of a known distance several sized gears are actually required to keep track of the leadscrew’s rotation and allowable drop in points."

So Tr0nd, if you can determine the Modulus and Pressure Angle, we should be able to help you find a source for the other gears.

Or you could try to contact Holzmann https://www.holzmann-maschinen.at/EN/retailer#haendler2

Holzmann Spare Parts: https://ersa.holzmann-maschinen.at/EN

"As metric threads are specified as a pitch, and not generally fractions of a known distance several sized gears are actually required to keep track of the leadscrew’s rotation and allowable drop in points."

Thread Dial Indicator

www.mrjones.id.au

So Tr0nd, if you can determine the Modulus and Pressure Angle, we should be able to help you find a source for the other gears.

Or you could try to contact Holzmann https://www.holzmann-maschinen.at/EN/retailer#haendler2

Holzmann Spare Parts: https://ersa.holzmann-maschinen.at/EN