- Joined

- Apr 22, 2016

- Messages

- 965

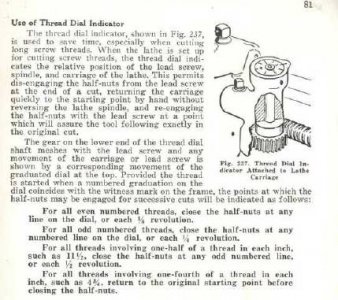

I thought I remembered that when using the TDI for any even thread you could use at least the even numbered lines. I was cutting a 18 TPI tread yesterday and had started with the 4 line but once changed to the 2 line and it cut a different place. Is this right or did I do something else wrong?

The leadscrew is 6 TPI, the TDI has 24 teeth, the dial is numbered 1 - 4 with intermediate lines and the carriage travel per one revolution of the TDI is 4".

I know I've seen some kind of a chart for this but can't seem to find it now.

Thanks

Aaron

The leadscrew is 6 TPI, the TDI has 24 teeth, the dial is numbered 1 - 4 with intermediate lines and the carriage travel per one revolution of the TDI is 4".

I know I've seen some kind of a chart for this but can't seem to find it now.

Thanks

Aaron