- Joined

- Apr 21, 2015

- Messages

- 589

The rifle sounds like fun.

When I first started with the hobby, I tried hard to stick to SAE tooling. I eventually caved, though, as I started working on more and more metric stuff.

Seems my biggest need for metric stuff is repair work: like it or not, the rest of the world is almost entirely metric, and much of the stuff I find myself repairing was made offshore. I've no real preference for most work, but SAE tooling and hardware is undeniably easier and cheaper to acquire in the US. I still can't single-point metric threads on the lathe, but I rarely have to do anything too big for taps and dies (and my collection of metric taps and dies is filling out nicely).

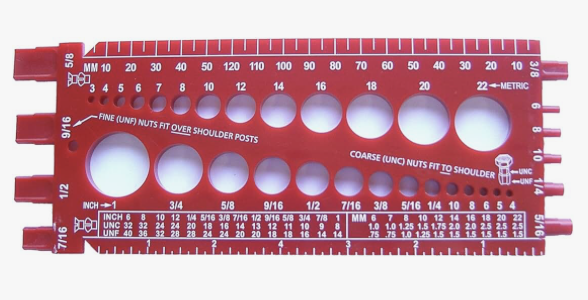

It definitely helps to have reliable gauges to distinguish between the two systems!

When I first started with the hobby, I tried hard to stick to SAE tooling. I eventually caved, though, as I started working on more and more metric stuff.

Seems my biggest need for metric stuff is repair work: like it or not, the rest of the world is almost entirely metric, and much of the stuff I find myself repairing was made offshore. I've no real preference for most work, but SAE tooling and hardware is undeniably easier and cheaper to acquire in the US. I still can't single-point metric threads on the lathe, but I rarely have to do anything too big for taps and dies (and my collection of metric taps and dies is filling out nicely).

It definitely helps to have reliable gauges to distinguish between the two systems!