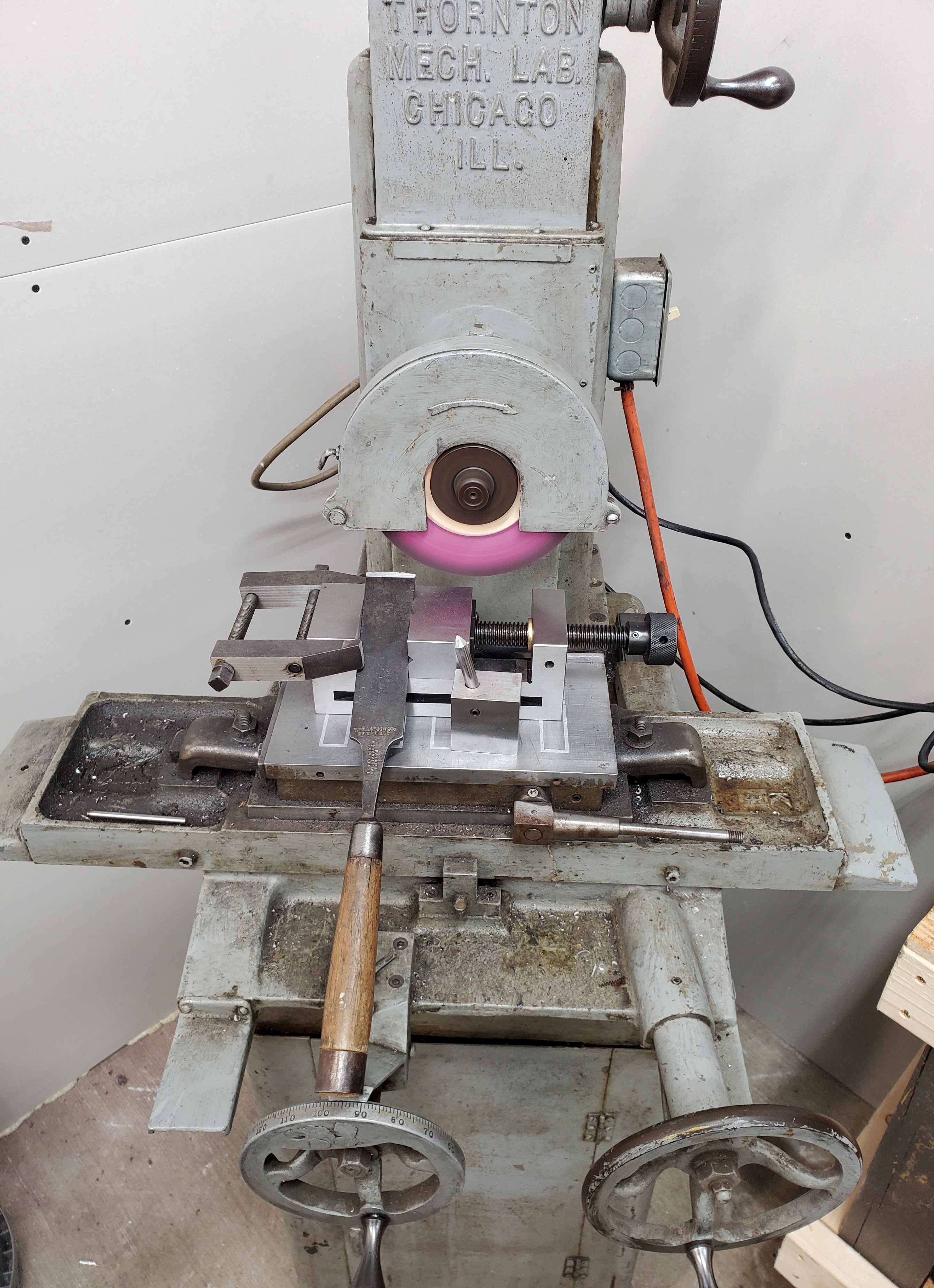

I've had this surface grinder for around 15 years or more. Starting out it didn't grind very nice but after I learned about clocking the wheel and better techniques the quality of the surface has gotten much better.

We really didn't know what oil to run in the spindle so we started out running SAE 30 non detergent. The seals leaked pretty badly starting out. All these years later the seals barely leak at all unless I put in a lot of oil. I usually fill the oil cup and warm up the machine, then refill it again.

The machine runs really smooth. It is extremely accurate and everything glides beautifully. I really love this machine and it is surprising to say that after the initial rough finish.

I don't know what I should be running in the spindle and Google is no help. I don't know if running a thinner oil will give me an even better finish. I do know I'm not getting much heat. I don't know if using such a thick oil had caused damage but the machine really runs nicely.

I am thinking I should try some 6 wt to 10 wt oil just for kicks.... I'm not entirely sure the thin oil won't just fall out of the old seals......

What do you think?

We really didn't know what oil to run in the spindle so we started out running SAE 30 non detergent. The seals leaked pretty badly starting out. All these years later the seals barely leak at all unless I put in a lot of oil. I usually fill the oil cup and warm up the machine, then refill it again.

The machine runs really smooth. It is extremely accurate and everything glides beautifully. I really love this machine and it is surprising to say that after the initial rough finish.

I don't know what I should be running in the spindle and Google is no help. I don't know if running a thinner oil will give me an even better finish. I do know I'm not getting much heat. I don't know if using such a thick oil had caused damage but the machine really runs nicely.

I am thinking I should try some 6 wt to 10 wt oil just for kicks.... I'm not entirely sure the thin oil won't just fall out of the old seals......

What do you think?