-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The quest for precision on a Sherline mill

- Thread starter EricB

- Start date

- Joined

- Jul 29, 2014

- Messages

- 2,737

This is why everybody should have a Bridgeport. It can be trammed in all axes to as precise as you want it to be.

- Joined

- Feb 15, 2020

- Messages

- 375

non-sequiturThis is why everybody should have a Bridgeport. It can be trammed in all axes to as precise as you want it to be.

- Joined

- Dec 2, 2012

- Messages

- 1,723

This is why everybody should have a Bridgeport. It can be trammed in all axes to as precise as you want it to be.

I want a bridge port but I would have to run it with the head tilted all the time to fit it in the room

Stu

- Joined

- Feb 15, 2020

- Messages

- 375

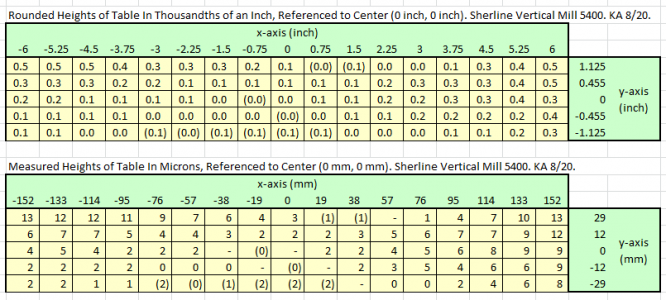

At long last I replaced the table on the 5400 mill. Checking with a micrometer revealed that the old table is thicker at the back by .001" - .002" than corresponding points on the front, measured between the top of the table to the bottom sliding surface that contacts the saddle, so it tapers toward the front. It also bulges in the center by about .001" compared with the ends, so it tapers toward each end. Must have been made on a Monday.

The new table is flat and square.

I still need to adjust everything but the built in error along the Y axis is now just over .001", which should be acceptable. I can see now that the remaining error is in the saddle. I can compensate for it with shims under whatever I mount to the table, if needed. Perhaps it's time for that tooling plate.

The new table is flat and square.

I still need to adjust everything but the built in error along the Y axis is now just over .001", which should be acceptable. I can see now that the remaining error is in the saddle. I can compensate for it with shims under whatever I mount to the table, if needed. Perhaps it's time for that tooling plate.

- Joined

- Feb 15, 2020

- Messages

- 375

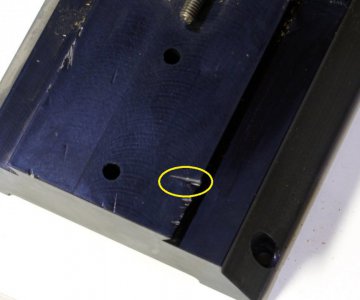

Spent the day adjusting. It turned out that some of the "cosmetic" damage from when it was shipped to me was real damage that was causing part of my problems. To be fair, when I bought this thing I was only vaguely aware of how to use it and had no means to check it's alignment, so I just dressed off the sharp edges and put it to work.

To start I installed the tooling plate and shimmed between it and the table to reduce the effect of the machine's built in error on my adjustments. Then I checked the plate with an indicator in the spindle while moving the table on the y axis at multiple points on the x axis. OK so far.

Next I swept indicator across the table front to back. This reading was almost .005" and showed the column was leaning forward. I needed to add a shim at the front of the column base so I took it off to clean any debris and oil that had made it under that small gap machined down the center of the column base. With the column removed I noticed that the oil had wicked up under one side of the column and not the other. One of the damaged areas was upset enough to make a gap on that side and the oil found it, so I scraped and filed and checked the surface with an indicator until it was true. Then I shimmed the column (several times) and swept the table again. Error gone.

I had upgraded to the 15" column bed some time ago, but now after fixing the base the bed was leaning to that side .002". This adjustment was trivial, as was the alignment of the headstock. I think I have a good machine now that is precise as I can make it without altering or replacing the mill saddle.

Sherline's instructions say that the table's built in error can be accounted for when making final adjustments. I'm thinking those adjustments should show (be off by) the amount of the error, otherwise you're just hiding it in your parts. I think I'm going to put up a sign next to the machine to remind me about it.

Here are some pictures of the damage I ignored. The packing material was just plastic padded envelopes. Those where just cut to pieces between the metal parts, no protection at all. Even with repair parts and upgrades I still have a ways to go to get to the cost of a new machine.

To start I installed the tooling plate and shimmed between it and the table to reduce the effect of the machine's built in error on my adjustments. Then I checked the plate with an indicator in the spindle while moving the table on the y axis at multiple points on the x axis. OK so far.

Next I swept indicator across the table front to back. This reading was almost .005" and showed the column was leaning forward. I needed to add a shim at the front of the column base so I took it off to clean any debris and oil that had made it under that small gap machined down the center of the column base. With the column removed I noticed that the oil had wicked up under one side of the column and not the other. One of the damaged areas was upset enough to make a gap on that side and the oil found it, so I scraped and filed and checked the surface with an indicator until it was true. Then I shimmed the column (several times) and swept the table again. Error gone.

I had upgraded to the 15" column bed some time ago, but now after fixing the base the bed was leaning to that side .002". This adjustment was trivial, as was the alignment of the headstock. I think I have a good machine now that is precise as I can make it without altering or replacing the mill saddle.

Sherline's instructions say that the table's built in error can be accounted for when making final adjustments. I'm thinking those adjustments should show (be off by) the amount of the error, otherwise you're just hiding it in your parts. I think I'm going to put up a sign next to the machine to remind me about it.

Here are some pictures of the damage I ignored. The packing material was just plastic padded envelopes. Those where just cut to pieces between the metal parts, no protection at all. Even with repair parts and upgrades I still have a ways to go to get to the cost of a new machine.

Attachments

- Joined

- Mar 3, 2020

- Messages

- 506

Eric I feel your pain.

this is how UPS left a 4 jaw chuck on my front porch few yrs ago.

The chuck was not damaged other than a few scratch’s, & screws missing.

No problem

BTW, I’m checking out your PM#5 build, (thanks for that) I’m finally working on mine again.

Cheers

this is how UPS left a 4 jaw chuck on my front porch few yrs ago.

The chuck was not damaged other than a few scratch’s, & screws missing.

No problem

BTW, I’m checking out your PM#5 build, (thanks for that) I’m finally working on mine again.

Cheers

Attachments

- Joined

- Feb 15, 2020

- Messages

- 375

Eric I feel your pain.

this is how UPS left a 4 jaw chuck on my front porch few yrs ago.

The chuck was not damaged other than a few scratch’s, & screws missing.

No problem

BTW, I’m checking out your PM#5 build, (thanks for that) I’m finally working on mine again.

Cheers

Some things have to be blamed on the shipper too. I would think that something that heavy would be in a more robust container, perhaps fixed to a hunk of plywood.

My PMR #5 shows all the alignment defects I've been sorting out in my machines. I'm really surprised it works. At some point I'll have to build another one.

- Joined

- Mar 3, 2020

- Messages

- 506

Yeah, should of worded that differently.

didn’t mean to blame UPS.

When CME shipped my 5X7 tilting angle plate across the country from Michigan it was packaged so robustly I don’t think it could of possibly been injured.

didn’t mean to blame UPS.

When CME shipped my 5X7 tilting angle plate across the country from Michigan it was packaged so robustly I don’t think it could of possibly been injured.

- Joined

- Feb 15, 2020

- Messages

- 375

BTW, I’m checking out your PM#5 build, (thanks for that) I’m finally working on mine again.

Cheers

Be sure to share your progress!