- Joined

- Jun 7, 2013

- Messages

- 10,111

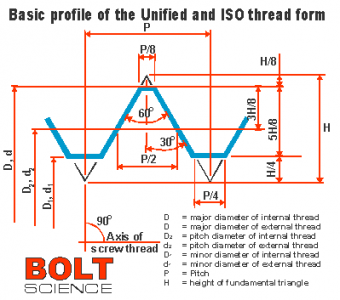

The #210 is only used for comparative measurements and is faster to use, the 575 series is used to measure pitch diameter, but is fairly fussy to use resulting in more time used up. If I was making a thread gauge, I would be using the 575, if I was threading most other work, I'd be getting close to finish and be using a nut or gauge for the final fit unless specs were called out for a pitch diameter.