- Joined

- Oct 27, 2013

- Messages

- 124

Hi all!

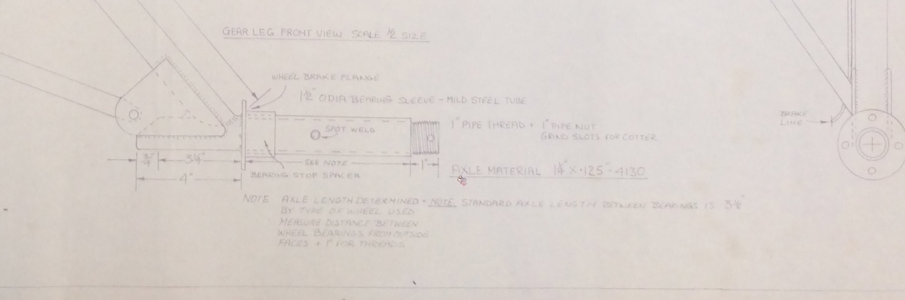

I am building an axel assembly to blue prints for a rag and tube airplane. The wheel axel detail on the blueprints shows a 1" pipe thread on the end to retain the wheel bearings on the sleeved portion of the axel. The prints call for a 1" pipe nut drilled for a cotter pin.

Pretty straight forward and I probably have a friend with a pipe threading machine that will be able to thread the end of the .125 thick 4130 steel tube I'll use. I know male pipe threads are tapered, but I can't seem to find a source for a large pipe nut. Are female pipe nuts also threaded?

I am building an axel assembly to blue prints for a rag and tube airplane. The wheel axel detail on the blueprints shows a 1" pipe thread on the end to retain the wheel bearings on the sleeved portion of the axel. The prints call for a 1" pipe nut drilled for a cotter pin.

Pretty straight forward and I probably have a friend with a pipe threading machine that will be able to thread the end of the .125 thick 4130 steel tube I'll use. I know male pipe threads are tapered, but I can't seem to find a source for a large pipe nut. Are female pipe nuts also threaded?