- Joined

- Dec 13, 2012

- Messages

- 466

Turning tapers can be a pain without a taper attachment. Moving the tailstock means that you have to put it back.

Using a boring head from the mill is another simple way of doing it. I will show that in detail later.

You do need a couple of special things.

1. A Morse Taper shaft for your boring head to fit you tail stock.

2. A live center without a Morse Taper but a shaft diameter to fit your boring head.

I will come back to number 2 later in this post.

Number 1 is easier, but a little pricey. For example my boring head is small with a thread of 7/8-20 and enco has them for $30.

But on ebay I found one for $10 with shipping, but it has 1/2-20 threads. Being cheap like I am I decided to adapter it.

These are the steps I took.

I started with this:

I cut the tang off of it (not necessary) and Turned, Tapped and Faced off the correct size of material

The I mount it in the headstock using the morse taper itself so I know it will be nice and true.

To make sure it doesn't un-thread I drilled a hole from the end in half of each part and drove in a roll pin.

Here I'm cutting the roll pin flush.

Then I form a blank for the threads.

Then thread it.

And it fits!

Here is is completed

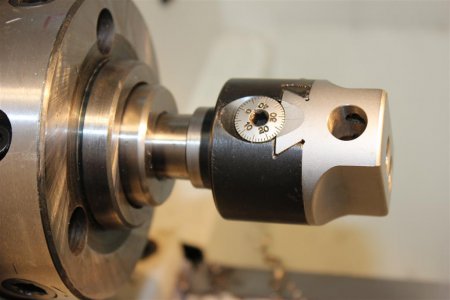

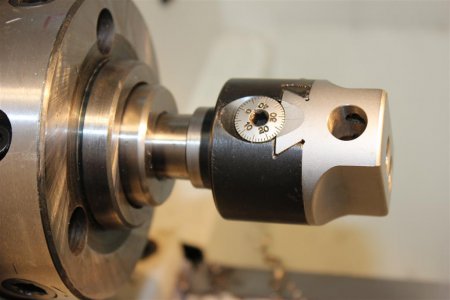

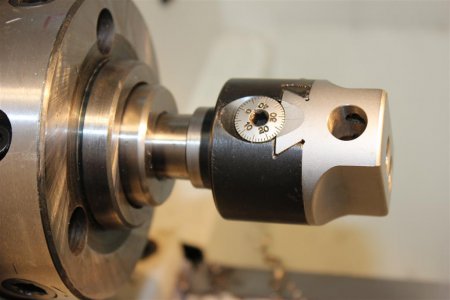

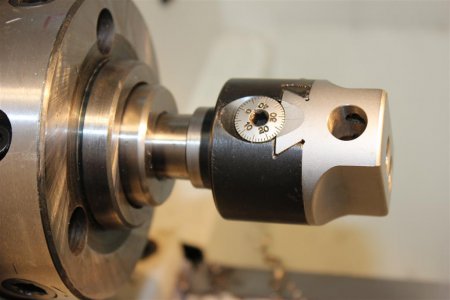

And installed

As soon as I get the live center I ordered I'll show what I do to that.

Gary

View attachment 97954

View attachment 97954

Using a boring head from the mill is another simple way of doing it. I will show that in detail later.

You do need a couple of special things.

1. A Morse Taper shaft for your boring head to fit you tail stock.

2. A live center without a Morse Taper but a shaft diameter to fit your boring head.

I will come back to number 2 later in this post.

Number 1 is easier, but a little pricey. For example my boring head is small with a thread of 7/8-20 and enco has them for $30.

But on ebay I found one for $10 with shipping, but it has 1/2-20 threads. Being cheap like I am I decided to adapter it.

These are the steps I took.

I started with this:

I cut the tang off of it (not necessary) and Turned, Tapped and Faced off the correct size of material

The I mount it in the headstock using the morse taper itself so I know it will be nice and true.

To make sure it doesn't un-thread I drilled a hole from the end in half of each part and drove in a roll pin.

Here I'm cutting the roll pin flush.

Then I form a blank for the threads.

Then thread it.

And it fits!

Here is is completed

And installed

As soon as I get the live center I ordered I'll show what I do to that.

Gary

View attachment 97954

View attachment 97954