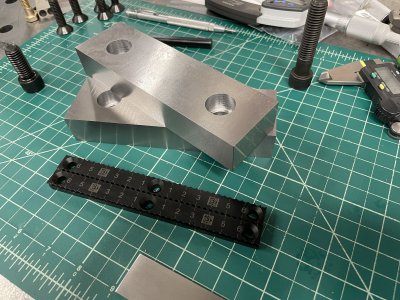

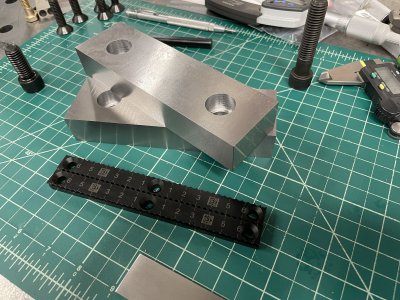

Found a set of NIB TalonGrip vise jaw strips for 6" jaws on eBay, and made a pair of jaws to mount them in. Already had a couple bars of 4140 that were in the ballpark size wise. Being only around 30HRC, they're going to get scratched and dinged up, but until I get a heat treat oven, so be it.

After squaring them up on the mill, and then grinding them together, they wound up .9975"x1.7850"x6.00". The factory jaws from MiteeBite are 1.00"x1.740"x6.00", I believe. Close enough. Made the counterbored holes for the 1/2"-13 SHCS.

Lastly, the groove was cut to accept the serrated jaw strips. It's .188" deep and leaves a .125" ledge in front of the serrations. The width called for .500" +.001"-.003". I started at .005" and then gradually opened it up until the strips just started in the slot, and stoned them until they just fit. Drilled and tapped for the 10-32 mounting screws, and then broke the edges with a .010" chamfer. Look forward to giving them a try with aluminum and mild steel.

After squaring them up on the mill, and then grinding them together, they wound up .9975"x1.7850"x6.00". The factory jaws from MiteeBite are 1.00"x1.740"x6.00", I believe. Close enough. Made the counterbored holes for the 1/2"-13 SHCS.

Lastly, the groove was cut to accept the serrated jaw strips. It's .188" deep and leaves a .125" ledge in front of the serrations. The width called for .500" +.001"-.003". I started at .005" and then gradually opened it up until the strips just started in the slot, and stoned them until they just fit. Drilled and tapped for the 10-32 mounting screws, and then broke the edges with a .010" chamfer. Look forward to giving them a try with aluminum and mild steel.