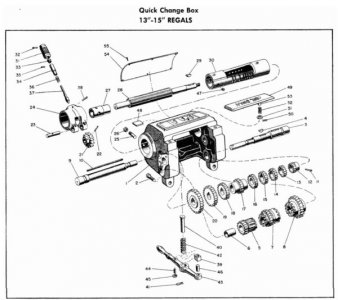

In my quest to take apart every major component of my lathe and clean it, I am now down to one of the final parts, the quick change gear box.

BTW if you think I'm crazy for taking all this stuff apart, lets just say nothing on this lathe could be operated effectively (aka sh*t was stuck in place). You can see how gross it is in the picture below, and that is after I already cleaned it as effectively as I could before I started taking it apart. Most of this machine required me to use a screw driver to carefully scrape away hard grime before I could even tell the difference between the castings and a bolt, nut, or screw.

Back on topic.

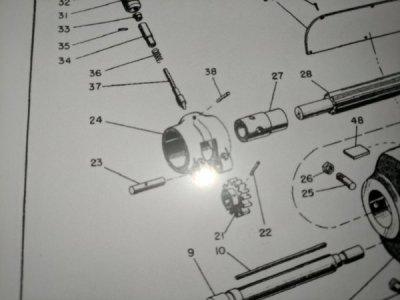

I got all the gears removed but I cannot for the life of me figure out how to get the tumbler gear (21) out so that I can remove the yoke (24). The yoke sits on cylinder (30) but the tumbler gear prevents it from sliding off either end without being removed.

I know I have to remove the shaft (23) but seeing as it is inside of a very tight space inside of the gear box, its not like I can get a hammer or punch to either side of it and actually be able to tap it.

Anyone have any ideas on how I would remove the tumbler gear shaft (23)?

Also fun note, pin (22) was absent. The hole is there, but the pin was either misplaced/fell out/never installed

BTW if you think I'm crazy for taking all this stuff apart, lets just say nothing on this lathe could be operated effectively (aka sh*t was stuck in place). You can see how gross it is in the picture below, and that is after I already cleaned it as effectively as I could before I started taking it apart. Most of this machine required me to use a screw driver to carefully scrape away hard grime before I could even tell the difference between the castings and a bolt, nut, or screw.

Back on topic.

I got all the gears removed but I cannot for the life of me figure out how to get the tumbler gear (21) out so that I can remove the yoke (24). The yoke sits on cylinder (30) but the tumbler gear prevents it from sliding off either end without being removed.

I know I have to remove the shaft (23) but seeing as it is inside of a very tight space inside of the gear box, its not like I can get a hammer or punch to either side of it and actually be able to tap it.

Anyone have any ideas on how I would remove the tumbler gear shaft (23)?

Also fun note, pin (22) was absent. The hole is there, but the pin was either misplaced/fell out/never installed