-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tail stock die holder

- Thread starter Aukai

- Start date

- Joined

- Jul 20, 2012

- Messages

- 1,238

I was taught the hex were for chasing and round for cutting.

Interesting, an old wives tail then.

Probably one of those things where both statements are true but the lines on that got blurred along the way on use of the tool. So what was taught was true and what is now use of the tools is also true.

I wonder if the reason is making the hex dies themselves and how people were using them. Maybe what started out as thread chasers led to guys cutting new threads with those and manufacturers just changing them so they also cut new threads?

I have an old Craftsman hex set also. Cut many new threads with them.

If they are just for thread chasing then why do they have the long bevel on the starting side? Not arguing just trying to learn.

Chuck

If they are just for thread chasing then why do they have the long bevel on the starting side? Not arguing just trying to learn.

Chuck

- Joined

- Jan 31, 2016

- Messages

- 11,475

Hi Mike , got your message last night and returned one . Be back late tonight from SC , be driving 530 miles this afternoon . Had a wonderful rain free 10 days down here at Surfside Beach but it's time to get back to work  I'll be in touch about some TS die holders .

I'll be in touch about some TS die holders .  Dave

Dave

- Joined

- Jul 19, 2013

- Messages

- 590

Hex Dies are only for re-threading not for cutting threads....

Round dies are made for cutting threads....

This is generally true. But there are exceptions.

For my lathe I have purchased two 4" 4-jaw lathe chucks which have #2 Morse taper mounts. One is a fixed mount and the other a ball bearing mount, which I use with (proper) round dies for threading by hand or starting threads. These chucks handle every size die I have.

- Joined

- Sep 28, 2013

- Messages

- 4,317

this thread has reminded me that I need to make a tap adapter for my tailstock die holder

Here's mine, as simple as it gets

if you leave a little length on the shaft, you can also use it to push dies out of the holder when you're done

I don't use it all that often, but it is very useful when I do need it. Way faster than single point threading for conventional thread sizes. I use a mix of solid (old HF set) and split dies. If I were to use hex dies I'd simply make an adapter out of an old socket as someone posted above

Here's mine, as simple as it gets

if you leave a little length on the shaft, you can also use it to push dies out of the holder when you're done

I don't use it all that often, but it is very useful when I do need it. Way faster than single point threading for conventional thread sizes. I use a mix of solid (old HF set) and split dies. If I were to use hex dies I'd simply make an adapter out of an old socket as someone posted above

- Joined

- Dec 20, 2012

- Messages

- 9,422

I think tailstock die holders are useful for smaller thread sizes. Once you get up to about 3/8" diameter, the problem is holding the work solid in the lathe chuck; the torque required to thread round stock gets too high and the work spins. If you are doing larger threads, at least partially screw cut it and finish it with a die.

I figure if I'm going to partially screw cut something then I may as well fully screw cut that thing. Hence, I rarely use dies anymore.

I figure if I'm going to partially screw cut something then I may as well fully screw cut that thing. Hence, I rarely use dies anymore.

Last edited:

- Joined

- Nov 9, 2015

- Messages

- 407

I did something very similar. To make a hex die adapter, I started with a $7.00 die stock off Ebay, sawed the handles off, and turned it round. Then I made a collar to fit my 1.5" round die holder and press fit the dismembered die stock into the collar.I made a Hex die holder from a large socket that I cut down and inserted into the die body. Little bit of Loctite and it's worked well. If the Loctite fails I'll drill and tap for a set screw.

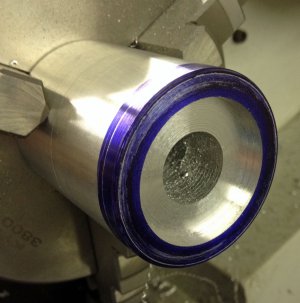

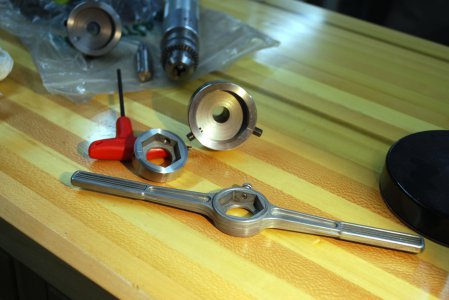

Here are a couple of photos showing the front, and back of the hex die adapter:

The Front:

The Back:

And a die stock very similar to the one I modified to fit tailstock die holder:

Last edited: