I bought one of those inexpensive LED tachometers off eBay but it didn't come with any wiring instructions or diagrams. Can't expect much for $9 I guess.

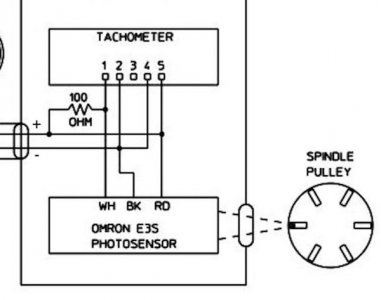

After searching a bit I found some basic info on the probe wires and tach terminals. I've attached a diagram of how I believe it's supposed to be wired.

What I found for the probe is the brown wire is 12 vdc+, the blue wire is 12 vdc-, and the black wire is signal. The tach has five terminals and what little info I found is terminal 1 is signal input, terminal 2 is signal ground, terminal 3 is NC, terminal 4 is input voltage "+", and terminal 5 is is input voltage "-".

In my diagram the black probe wire is connected to terminal 1 (signal input), the blue probe wire is connected to terminal 2 (signal ground), and the brown probe wire is connected to terminal 3 (NC). The 12 vdc power supply is connected as shown.

I'm still working on the installation so I haven't tested anything yet to see if it will work. Not sure if my wiring is incorrect if it will smoke the tach.

Let me know what you think.

Tom S.

After searching a bit I found some basic info on the probe wires and tach terminals. I've attached a diagram of how I believe it's supposed to be wired.

What I found for the probe is the brown wire is 12 vdc+, the blue wire is 12 vdc-, and the black wire is signal. The tach has five terminals and what little info I found is terminal 1 is signal input, terminal 2 is signal ground, terminal 3 is NC, terminal 4 is input voltage "+", and terminal 5 is is input voltage "-".

In my diagram the black probe wire is connected to terminal 1 (signal input), the blue probe wire is connected to terminal 2 (signal ground), and the brown probe wire is connected to terminal 3 (NC). The 12 vdc power supply is connected as shown.

I'm still working on the installation so I haven't tested anything yet to see if it will work. Not sure if my wiring is incorrect if it will smoke the tach.

Let me know what you think.

Tom S.