-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swivel vise insert for fixed vise

- Thread starter Maplehead

- Start date

I'm not following that.If you're milling the ends , why not use a sine bar or protractor in your stationary vise ?

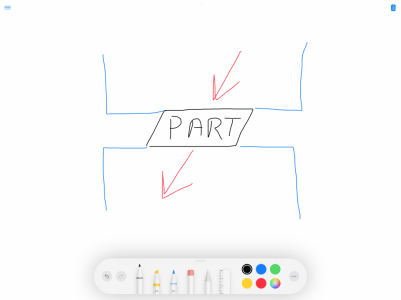

I need to have the part clamped down along the long flats and then swivel the part for the end mill to cut parallelto the short sides, as seen in my drawing.

Attachments

I thought of that but the fixture, I figured, would have some kind of clamping mechanism so why not just go with a smaller removable vise.If it’s a part you plan to do repeatedly why not just build a fixture?

- Joined

- Nov 17, 2020

- Messages

- 1,723

The Sherline milling vise is sized just right to be the perfect working companion to the Sherline milling machine. The jaws are 2.00″ (50.8mm) wide by 1.00″ (25.4mm) deep and open a full 2.00″ (50.8mm). The fixed jaw has both a horizontal and vertical “V” groove to facilitate holding round bar stock. The vise includes two clamps for use in attaching it to the milling machine. These clamps are the same as the 4-jaw hold-down set.Yup, G0678 knee mill.

I was thinking something like this but I cannot find overall dimension specs for this anywhere.

Based on the above.. i would say that your looking at about 3.5 inches wide at most prob.. for the swivel base

A simpler and more secure way is to use this kind of digital protractor to set the angle of the vice. The slots on the table can be used as the reference for angle zero. https://www.amazon.com/iGaging-Digital-Protractor-Stainless-Bladed/dp/B00AEIB3Y0