- Joined

- Jan 11, 2013

- Messages

- 1,821

This thread is part demo, and part request for advice.

Since I got a surface grinder (two now, actually), I've been grinding everything I can get my hands on. Watch out Rover. So I remembered acquiring an old cast iron lapping plate a while back, concerned it was probably out of flat. So I decided to throw it on the surface grinder to bring it back.

Besides knowing not to grind so much away that I lose the grooves for retaining the lapping compound, is there anything that wouldn't be obvious to me about methods to bring this lapping plate back to it's original usefulness, and finish it properly?

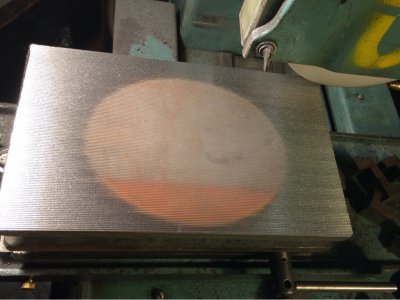

For those who want to know, I have ground down almost .005, and look at the pattern that is still not completely true'd up yet!

Bernie

Since I got a surface grinder (two now, actually), I've been grinding everything I can get my hands on. Watch out Rover. So I remembered acquiring an old cast iron lapping plate a while back, concerned it was probably out of flat. So I decided to throw it on the surface grinder to bring it back.

Besides knowing not to grind so much away that I lose the grooves for retaining the lapping compound, is there anything that wouldn't be obvious to me about methods to bring this lapping plate back to it's original usefulness, and finish it properly?

For those who want to know, I have ground down almost .005, and look at the pattern that is still not completely true'd up yet!

Bernie