I have a 7 x 12 mini-lathe. I am trying to bore a hole to match a shaft, which measures slightly over 0.750." I have an 11/16" drill, so after a pilot hole, and an 11/16" drill, I started to bore. It seems like I am not making much progress. 11/16" is .6875. 0.750 - 0.6875 = 0.0625. Looking at the dial on the cross slide, one revolution should be 0.040". I believe that the cross slide motion should produce a change in dimeter of twice the motion of the cross slide. (Am I wrong?).

You might be. Some lathes calibrate the cross slide dial to read tool movement, others calibrate it to read diameter change. It is up to you to understand your lathe. Make a sharpie mark on the cross-slide, turn it 10 or 20 or some other convenient number of revolutions, and then use a 6" scale to see whether it moved 0.040 or 0.080 or 0.020 per rev. (I'm guessing from the 0.040 in your post that it has a metric lead screw...) Once you understand how your lathe works, write it down for future reference.

So a single revolution of the dial should change the diameter of the bore 0.080". However, I have turned the dial several revolutions, and the diameter is still less than 0.750".

You should be measuring the bore after every cut. Later, once you have confidence in your machine, tooling, and process you can skip some measurements but you should always be measuring as you get close to final size.

If you don't know how much you are taking off (or not) on each pass you are working totally blind.

What tools do you have for measuring inside diameters? For 0.750, the options are:

A) Inside jaws on your dial calipers. Only accurate to a couple thou on a good day, several thou on a bad day. And can't measure deep holes.

B) Telescoping gage and outside jaws on the calipers. Good to a couple thou, some skill/practice is needed to operate.

C) Telescoping gage and micrometer. Can be good to a fraction of a thou but skill and a good touch is needed to get that accurate.

D) Gage pins. Accurate to a thou or so, no skill required, but most people don't have a set.

E) Dial bore gage. Can be accurate to better than a thou, but not something most beginners have. And still requires a bit of skill as well as a standard to set it to.

I strongly recommend option C. If you don't have a set of telescoping gages, get some and learn how to use them. The cheapest import sets are under $20 (Harbor freight has a set for $17.99). Mid-range imports are $20-50. Mitutoyo is $150-200 for a new set of 6, about $100 for a set of 3 that covers up to 2" holes. Less for used sets on eBay. Let your budget be your guide, but keep in mind that you will use them every time you do an ID measurement.

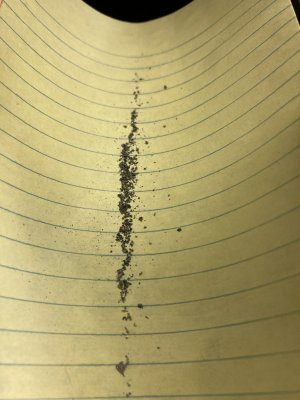

I am using a boring bar that sticks 2" past the end of the holder. I can see the lack of rigidity in my lathe, of course. I can see some chips, so it is not like it is not cutting at all.

Deflection is almost certainly part of your problem, but 0.040" or more seems like a lot. Maybe the boring bar isn't tight enough in the holder, or the holder is slipping on the compound, or the cutter/insert is slipping in the boring bar.

Are you trying to bore 2" deep? The boring bar should stick out as little as possible to achieve the hole depth that you need.

What kind of cutting tool are you using? How sharp is it? Is the geometry appropriate for the cut and the material? Are you sure the height is set right? All of those things could cause it to rub instead of cutting, which in turn might make something deflect or slip.

Am I just kidding to think that I can bore a hole with my mini-lathe? I could post a video if that would help. It looks like the site supports videos......

Richard

You should be able to bore a hole with that machine. The deeper you go the harder it will be to hold a tight tolerance, but 0.040 isn't a tolerance at all. Something is grossly wrong.

Try posting pictures of your tooling and setup. Video might be useful, but photos are probably easier and often better.