- Joined

- Jun 19, 2017

- Messages

- 83

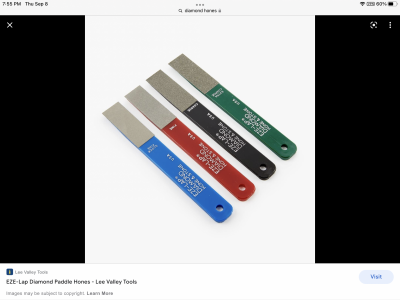

I have no way to sharpen any of my tooling. Is there a stone that is commonly used for that?

thx

edit,

i'm using brazed boring bars on my mill and i want to keep them sharp.

thx

edit,

i'm using brazed boring bars on my mill and i want to keep them sharp.

Last edited: