- Joined

- Oct 15, 2013

- Messages

- 298

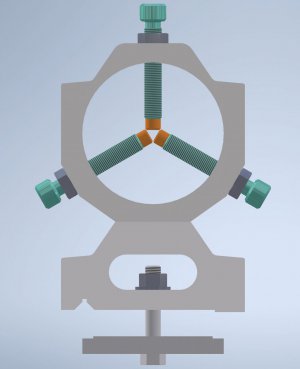

The Sheldon EXL 10" lathe I now own came to me without a proper steady rest. So... I don't have a steady rest, but I do have a long piece of aluminum extrusion. What's a guy to do?  Make one!

Make one!

What do you guys think about the steady that I've modeled up using this aluminum? Is that a reasonable design, and what would you do differently? (fyi- the thru hole is 4" dia, the extrusion is 5.20" wide across flats, adjusters are 1/2-20UNF)

Make one!

Make one!What do you guys think about the steady that I've modeled up using this aluminum? Is that a reasonable design, and what would you do differently? (fyi- the thru hole is 4" dia, the extrusion is 5.20" wide across flats, adjusters are 1/2-20UNF)