- Joined

- Nov 24, 2018

- Messages

- 239

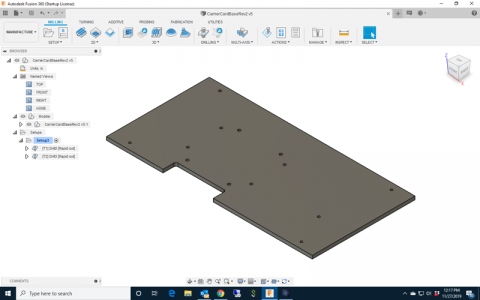

I've been playing with FreeCAD and think I'm getting used to the CAD part (Part Design workbench). Now, I'm trying to get the Path workbench running. I think I found a limitation. I have a 12" X 6" X 0.188" piece of Plexiglass (Acrylic) that needs 12 holes drilled into it of two sizes. I got that working.

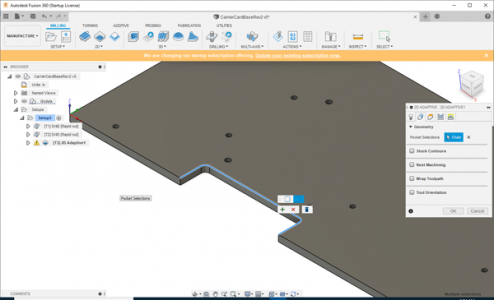

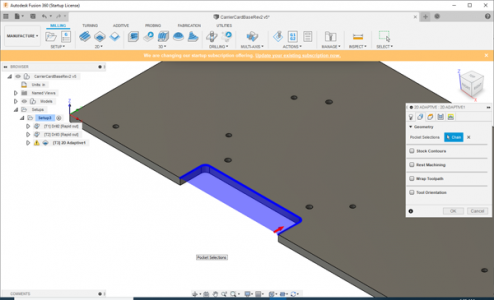

It also has a 0.750" deep by 2.930" cutout in it. I want to use a 1/4" endmill so I get a 1/8" radius on the internal corners. FreeCAD won't let me mill out just that area. It wants to go around the entire perimeter even though the piece is cut to final size. Obviously, I can't do that since I need to clamp this down on the mill table. I just want that cutout milled. I read a little and it seems this feature was removed a few revisions back. So, other than hand editing the G code output, what can I do?

I should leave this to somebody who actually uses that particular program, but generally, you can:

1. do a partial "open" chain of the feature.

2. You can sketch lines that can then be selected later as a machining boundary (which you should be able to keep the tool inside, centered on, or outside of). "Avoidance", "Air" and "Containment" are other names I've seen for features to help control a toolpath like this.