- Joined

- May 6, 2020

- Messages

- 63

Hi there,

I got this SM 2000 series 13 inches lathe, it is in overall good shape, some signs of negligence like mid rust due to bad storage, but not that bad.

It was already partially disassembled because the seller tried to move it to his basement with no success, I did a preliminary check of gear head and other than some wear un the spindle splines for advances, it looked good, I also noticed that heavy gear oil was used but I though it wasn't a big deal.

Well, at first run test, I heard gears grinding in headstock at mid speed, then at high speed the motor struggles to run.

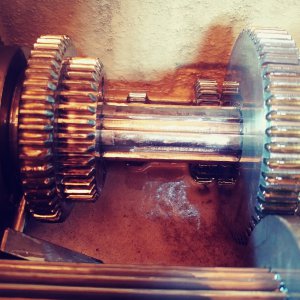

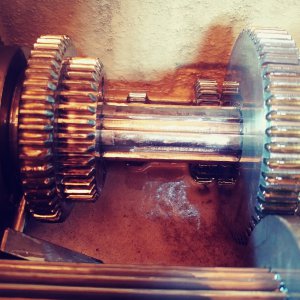

Looking closer I found what it seems to be some kind of weird crash-save, in the intermediary shaft, the splines looks roughly regrinded and gears over it has visible wooble.

It s almost like if the shaft was broke then welded back and regrinded :s

First, how is it even possible?.

Second, how bad is it? can I just run it and endure the noise?

Third, SM claims to sell/build any part for their lathes even obsolete ones, how much would it cost?

Fourth, can it be better repaired?

I got this SM 2000 series 13 inches lathe, it is in overall good shape, some signs of negligence like mid rust due to bad storage, but not that bad.

It was already partially disassembled because the seller tried to move it to his basement with no success, I did a preliminary check of gear head and other than some wear un the spindle splines for advances, it looked good, I also noticed that heavy gear oil was used but I though it wasn't a big deal.

Well, at first run test, I heard gears grinding in headstock at mid speed, then at high speed the motor struggles to run.

Looking closer I found what it seems to be some kind of weird crash-save, in the intermediary shaft, the splines looks roughly regrinded and gears over it has visible wooble.

It s almost like if the shaft was broke then welded back and regrinded :s

First, how is it even possible?.

Second, how bad is it? can I just run it and endure the noise?

Third, SM claims to sell/build any part for their lathes even obsolete ones, how much would it cost?

Fourth, can it be better repaired?