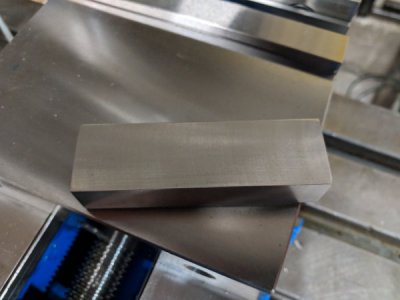

So, I wanted to work on a project and decided to practice squaring stock on the Bridgeport. Grabbed the fly cutter and promptly killed the HSS bit running too fast.  Yeah, I know, my own fault. I didn't account for the material difference and was set up for aluminum. The HSS did not like 1018 @1000 RPM and 2" on the fly cutter. Go figure.

Yeah, I know, my own fault. I didn't account for the material difference and was set up for aluminum. The HSS did not like 1018 @1000 RPM and 2" on the fly cutter. Go figure.

So I can regrind it and run at a much more sane 100 RPM or so. But that seems like it will take a while as I would need a matching slow feed rate. I could live with that, but it's nice to know what options are out there.

I tried a 3/8" carbide endmill. Worked great, though once I ran the numbers I was babying it and it probably would have worked better with higher RPM and feed. A larger carbide endmill might be an option here.

The insert based fly cutters and face mills seem like they would work faster, but I know I've read that interrupted cuts are not a great idea with inserts. This is working with about 1" material, so it would be interrupted. Eating inserts doesn't seem like a great plan. Even larger parts would have some interrupted cutting with a fly cutter at the ends. Are the inserts used for these tools somehow better for interrupted cuts?

So I can regrind it and run at a much more sane 100 RPM or so. But that seems like it will take a while as I would need a matching slow feed rate. I could live with that, but it's nice to know what options are out there.

I tried a 3/8" carbide endmill. Worked great, though once I ran the numbers I was babying it and it probably would have worked better with higher RPM and feed. A larger carbide endmill might be an option here.

The insert based fly cutters and face mills seem like they would work faster, but I know I've read that interrupted cuts are not a great idea with inserts. This is working with about 1" material, so it would be interrupted. Eating inserts doesn't seem like a great plan. Even larger parts would have some interrupted cutting with a fly cutter at the ends. Are the inserts used for these tools somehow better for interrupted cuts?