I don't believe it to be anything to do with the motor assembly like I said it was freshly rebuilt by a motor shop before I got the mill running and I've only had it running for a month or so. I remember the bushing for the pulley on the motor being bronze though so it could only be the bushings for the pulleys in the head that would be plastic. I'll take a look in the H&W site I didn't think they had series 2 parts they're hard to come by.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spindle woes pt. 2.

- Thread starter Izzy

- Start date

Looks like they have what I need and for 100bucks cheaper than what I found! Still an expensive belt tho... I've got the machine tied up on a job right now but I'll have to dig into it a bit try to find the problem but as of now symptoms are pointing to the belt and bushings...

- Joined

- Mar 26, 2018

- Messages

- 8,408

Wow, my old step pulley is very quiet. I have heard the variable-cone heads are noisy. In fact, I was watching a Youtube video, this guy turned his mill on and you could hardly hear him talking.

Belt and bushings are less than a spindle overhaul.

Good luck.

Belt and bushings are less than a spindle overhaul.

Good luck.

- Joined

- Oct 3, 2015

- Messages

- 983

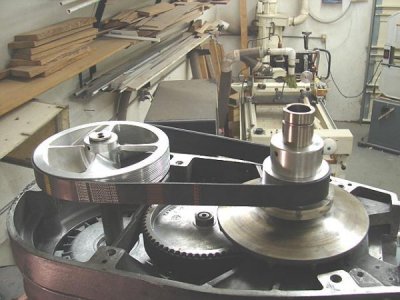

As the belt wears, the width diminishes, causing it to ride deeper in the pulleys. Typically the sharp outside edge will break down also. This will not only speed the spindle up, it will ride the shaft instead of the sheaves when it bottoms out. That will cause clatter.

It is best inspected off the machine.

It is best inspected off the machine.

So I looked inside the head the other day with a flash light and the bottom cover off. The edges of the belt still seem sharp to me. Also I can confirm the bushings on the motor pulleys are bronze! I can also confirm that the belt is not riding on the shaft I can see a clear contact patch from the belt on the pulley and it stops before the shaft. The pulleys in the head have bushings that are made of Babbitt, or tin or something of the like they where silver/greyish in color. I could shake the pulley by hand tho so I'm gonna go ahead and say thats where most of the noise is coming from. I ran the machine with the cover off and cranked the speed up and down while watching the belt and pulleys it looks like the moving in pulley in the head is getting stuck in it's travel at some point. Finally I lubricated the moving pulleys with a little spindle oil and sprayed some belt dressing on the belt. This quieted it down a bit but I'll have to address the bushings in the head at some point it's still noisy at high speeds.

Good deal you found a problem and bronze bushing are not expensive.And come in many different sizes which McMaster has a lot different sizes.But making these repairs may last you rest of your life so its a good investment.

It's absolutely going to get repaired just a matter of when! They don't make series 2 anymore but I love the thing it's a beast! Chrome hand scraped box ways, variable power feed on everything, spindle load meter, 4hp motor, 11x59 table. I have plans to do a full tear down and rebuild/restore some time in the future but untill then I just need to keep in running somewhat smoothly.

- Joined

- Oct 3, 2015

- Messages

- 983

Unfortunately vfd isn't an option for me for a few reasons. The biggest one being they don't make a 4hp vfd that goes from 220 single phase to 440 3 phase and if they do it's gonna cost 3x what I've got into the entire mill including tooling and labor costs! Don't get me wrong I think that's a great idea, and I'd probably run with it if I had a regular ole series 1 but its just not practical for me in my current situation.

I think for now I'll just finish up the mill work that has to be done then tear into it and order some bushings and belts. I indicated the inside of the spindle and had 0 measureable run out which made me feel much better about my spindle bearings and I feel much more confident in saying it's the bushing for the driven vari-disc that are causeing the noise.

Also the run out I was getting seems to be coming from the collet. I measure 0 run out everywhere till I put the collet in then I start getting some woble.

The spindle load meter I'm starting to think may be a separate issue possibly just a bad load meter.

I think for now I'll just finish up the mill work that has to be done then tear into it and order some bushings and belts. I indicated the inside of the spindle and had 0 measureable run out which made me feel much better about my spindle bearings and I feel much more confident in saying it's the bushing for the driven vari-disc that are causeing the noise.

Also the run out I was getting seems to be coming from the collet. I measure 0 run out everywhere till I put the collet in then I start getting some woble.

The spindle load meter I'm starting to think may be a separate issue possibly just a bad load meter.

Last edited:

I have King rich KRV3000 and BP clone with 4J head, and my head makes that noise and it's worse in back gear. My belt is brand new as I replaced it when I got the machine. I was suspecting bearings because a friend of mine has the smaller KRV2000 and his machine is quiet.

BTW my mill is 5hp and I run it from an eBay VFD, I did have to modify the wiring in the motor to bring out the star connection so it's now wired for 240V 3ph

BTW my mill is 5hp and I run it from an eBay VFD, I did have to modify the wiring in the motor to bring out the star connection so it's now wired for 240V 3ph