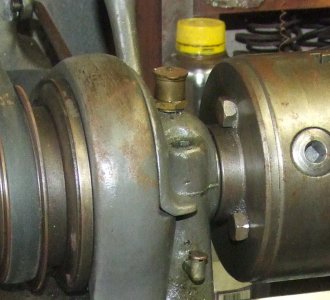

I finally got the motor assy. disassembled today. Thanks to the genius who pounded the head of the pin though the pulley, and then mushroomed the small end trying to push it back. Luckily I noticed the pulley was cracked on what appeared to be the small end (really the fat one) before I wasted any time.

Tip for those who don't know. Your local ACE Hardware carries a full line of tapered pins!

I got enough of the paint off the motor plate to see its a 1/3HP. That can't possibly be enough to run a 9" can it? Much respect to antique engineering if it is, I've got a new sealed 1HP laying around somewhere if it isn't, but it's really making me think twice about that DC motor.

Tip for those who don't know. Your local ACE Hardware carries a full line of tapered pins!

I got enough of the paint off the motor plate to see its a 1/3HP. That can't possibly be enough to run a 9" can it? Much respect to antique engineering if it is, I've got a new sealed 1HP laying around somewhere if it isn't, but it's really making me think twice about that DC motor.