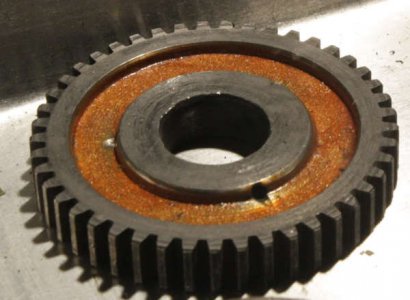

Hi Chad, There should be a stack of shims, some VERY thin, in the slit at the front of each bearing housing where the clamp bolt goes through. The bolt should be able to lock down tight on the shims and that will provide the correct spindle to bearing clearance. Not sure about getting a round hole with a hone in a bore with all those oil groove segments. With all respect to Greg, I think it best to avoid any form of abrasive material in a cast iron bearing, just in case some grit particles are retained after cleaning. Just be sure there are no burrs along the edges of the score marks. If the rest of the main bearing looks ok, I would be more concerned about the bearing surface of the spindle, especially if that blue colour is from overheating. If any metal has picked up on it, you can carefully take it off with a fine India Stone. If you decide to give it a polish, I would suggest 1200 paper, nothing coarser. The bearing surface was originally surface hardened and "superfinished", as SBL called it, probably by linishing as is done to engine crankshafts.

If you haven't stripped it right down yet, now might be a good time to just clean everything, slip the spindle in, no oil, and see if you can adjust the front bearing to get 0.001" movement horizontally and vertically. You may want to know where you're heading. Here's a vid that shows how its done:

http://www.youtube.com/watch?v=oS0DQusUR0w

If it seems ok, the score marks, as you suggest, won't matter at all. As long as the clearances are right and the spindle runs nicely with some oil, it will be great.

Sorry for the long post, and I hope I'm not trying to teach you how to suck eggs!

Regards, RossG

radial1951

_____________