All,

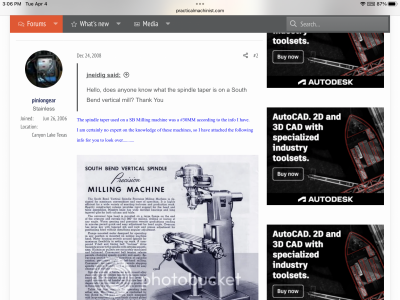

I am looking at a South Bend milling machine that is local to me. The overall machine seems okay. I have been looking for a smaller knee mill. One of the issues with this machine is that there is no tooling at all. it is long gone. (I guess scraped ;( ). The manual states is a No 30 Milling Machine Taper. Is there a modern equivalence? How is the taper held into the spindle,? Can tolling still be purchased? The manual states is a #30 Milling Machine Taper. Is there a modern equivalence? Other ideas? Of course, looking to keep the costs of tooling down. Please any ideas or comments are welcome.

Also open to other comments about these mills.

Thanks!!!!!

I am looking at a South Bend milling machine that is local to me. The overall machine seems okay. I have been looking for a smaller knee mill. One of the issues with this machine is that there is no tooling at all. it is long gone. (I guess scraped ;( ). The manual states is a No 30 Milling Machine Taper. Is there a modern equivalence? How is the taper held into the spindle,? Can tolling still be purchased? The manual states is a #30 Milling Machine Taper. Is there a modern equivalence? Other ideas? Of course, looking to keep the costs of tooling down. Please any ideas or comments are welcome.

Also open to other comments about these mills.

Thanks!!!!!